Special Alloy Pump

Special Alloy Pump

Overview

In engineering practice of urea nitrogen, acetic acid, acetic anhydride, chlor-alkali, Engineering Practice desalination and three acid (sulfuric acid, hydrochloric acid, nitric acid) and other processes, we have accumulated a wealth of experience in the production of special equipment selection and development. The main technical personnel participated in the national "65 Plan", "75 Plan" of major scientific and technological projects: " water-flooding pump for oil field corrosion resistant materials research ", "large-scale power plant water circulation pump hydraulic components corrosion resistant materials research", "compound fertilizer butterfly valves, diaphragm valves corrosion materials research "and other research work. In recent years, the major scientific and technological projects undertaken by our company included: Sinopec" hydrofluoric acid alkylation with high temperature valve research "," alkylation unit into the main fractionator development of the feed pump, Ministry of Science and Technology " tons class research of desalination key technologies and demonstration - high-voltage component development and demonstration research "," fertilizer plant methylamine pump bidirectional low carbon stainless steel research ". With the development of petrochemical industry, equipment working condition is more and more demanding, the company's research and development in special materials Pumps & Valves will meet all the requirements of corrosion resistance, wear resistance, high temperature, and other Pumps & Valves technology.

Achievement table

Metallurgy,Casting and Process

Company has rich precision casting experience of special materials and product research and development ability. Technical team members are mostly professional and technical experts in metal materials, metallurgy, casting, pumps and valves, etc. Our company has a 250KG medium frequency induction furnace, a 500KG medium frequency induction furnace, as well as advanced injection wax and dewaxing equipment, gas roaster, heat treatment and shot. We use precision silica sol and resin sand mould casting process. Annual output is 150 tons of special steel castings in the current. Performance of products is better in the petrochemical industry. The main casting products include titanium alloys, zirconium alloys, Monel, Inco nickel, HB / HC Hastelloy, precipitation hardening stainless steel, duplex stainless steel, Alloy 20, 904L, K alloy, nitric acid with C4, C6, C8 alloy, and so on.

"Lead the development of science and technology to create Huasheng brand". Hefei Huasheng Pumps & Valves provides high-quality products for users of special stainless steel and refine technology to create a new brand.

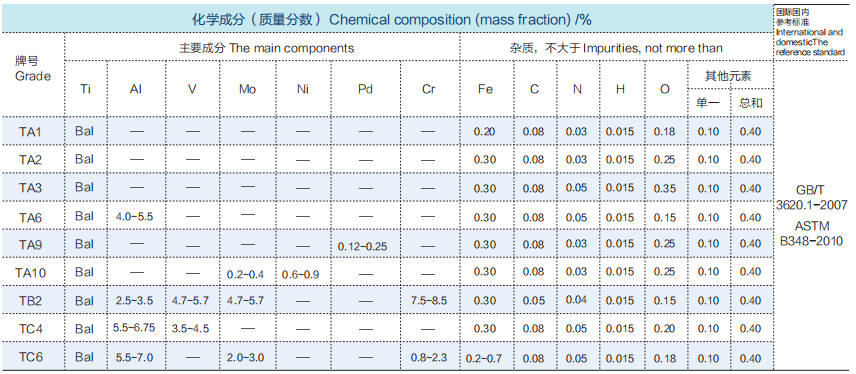

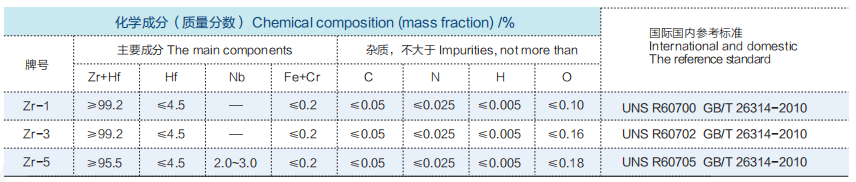

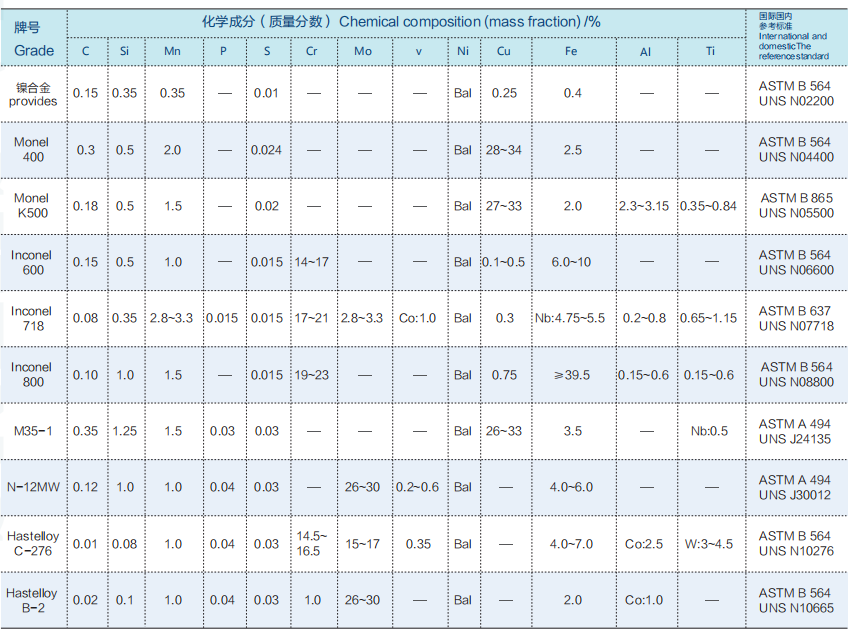

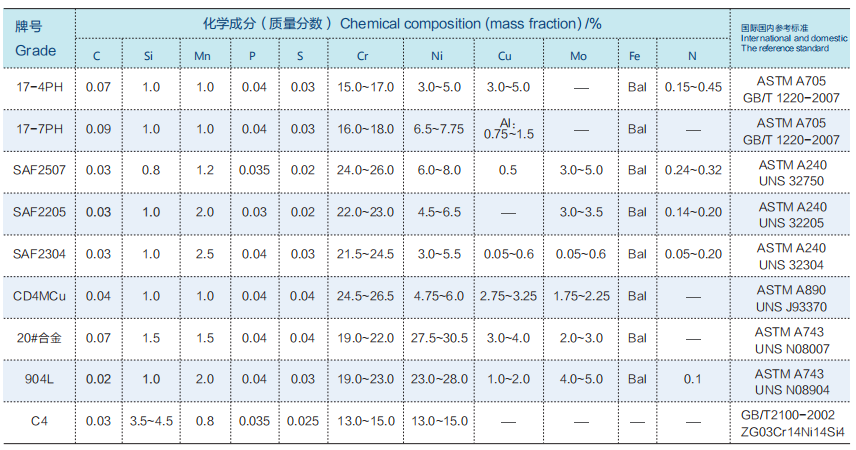

Main pump material composition and grade

1. Titanium and Titanium alloys and chemical composition

2. Zirconium and Zirconium alloys

3. Nickel-based alloys

4. Special stainless steel

Quality Assurance

The company had always pursued the principle that " The quality is the life of the enterprise ", and has developed a quality control objectives "strengthening quality management, optimizing product performance and ensuring the company's products in the domestic leading and international advanced", carrying strictly the ISO9001:2008 quality management system; ISO14001:2004 Environmental Management System; GB/T28001-2001 Occupational Health and Safety Management System III system certification requirements. The company focuses on staff training, job evaluation and internal audit system, in order to ensure the implementation of quality policy.

The product quality is always the top priority, from purchasing materials until to machining. In the purchase of raw materials sectors, Quality Testing Department detects the procurement of raw materials in accordance with the standard requirements, special material pump design development cycle, department of technology constitute expert team, in accordance with the performance requirements of the special material pump for developing special alloy pump technical assessment to ensure that the design quality. For Precision molding part of the special material pump, production department organizes experienced professional casting to guide the implementation.

Our company is also equipped with a laboratory to ensure the quality of products. In present, We have equipped with domestic advanced component testing and furnace detection equipment-LabSpark750A-type Spark direct reading spectrometer alloy, HBRVU-187.5-type optical Brinell-Rockwell-Vickers hardness tester, MR2000 inverted microscope and metallographic sample polishing machine, tensile testing machine, LASER-RE1200 three-dimensional laser scanner, etc. Raw materials and products can be fast and accurate analyzed.

In addition, the company is the long-term working closely with the Hefei University of Technology and other universities, building research platform of engineering technology research center of petrochemical and chemical pumps in Hefei. We could use research equipment of university (such as the Japanese electronics/scanning electron microscopy, energy dispersive spectroscopy and Rigaku / X-ray diffraction, etc.) in analyzing the microstructure of materials. In order to ensure product quality, by developing and implementing a strict process to optimize the microstructure of materials to further optimize the performance of materials.

-

Centrifugal pumps of AY series for petrochemical industry

-

High-Pressure Hydraulic Turbine Energy Recovery Units

-

HZX series self-priming centrifugal pumps

-

HX series of small flow chemical centrifugal pump