Centrifugal pumps of AY series for petrochemical industry

Centrifugal pumps of AY series for the petrochemical industry

Overview

Centrifugal pumps of AY series were new re-design of centrifugal pumps, which were based on centrifugal pumps of Y type and improvement of foreign advanced technology. The products were designed to the meet of modernization and energy saving as soon as possible, which had the following characteristics:

The original bearing body parts of 35, 50, 60 types were replaced by 45, 55, 70 types in turn, which improved the reliability of bearings;

Hydraulic parts adopted a hydraulic model of high-efficiency & Energy-saving, whose average efficiency was higher than the efficiency of a V-type oil pump;

To ensure inheritance, structure type, outline installation dimensions, performance range of AY-type pumps were designed the same with Y-type oil pumps, which were easy for old equipment’s upgrading and improving;

The material was selected, the body of the pump material is prior toⅡ, Ⅲ material, the body of bearing and other parts includes materials of steel, cast iron, which could provide a favorable condition for using outdoor and for marine in cold areas;

The pump’s components have a high degree of commonality, and the standard parts could be applied in all the several series of products.

Air cooling, fan cooling, water cooling are three kinds of bearing’s cooling, which was selected by the different pumping medium temperature. And the fan cooling is especially suitable to the area of lacking water or poorer water quality.

Seal flush was based on working conditions of the pump delivery medium, temperature, pressure, sealing liquid capacity of each pump chamber was as the following table,

The pressure of the sealing liquid was generally 0.07-0.1Mpa higher than the pressure of the sealed chamber. If the delivery medium was easily vaporized liquids, the pressure of the sealing liquid was generally 0.175-0.21Mpa higher than the pressure of the vaporization.

Stream piping was equipped when the temperature of the transmission medium reduced until precipitating crystals, and the pressure was about 0.1Mpa.

Seal the nominal diameter (mm) | 13~47 | 48~59 | 60~84 | 85~95 | 96~133 |

The average amount of liquid seal (m3/h) |

0.18 |

0.24 |

0.36 |

0.48 |

0.66 |

Model description

50 AY II60X2B 2500AYIII150C

50,250-pump suction diameter (mm)

AY-transformation of centrifugal pumps (first stage adopted double suction impeller)

Ⅱ, Ⅲ- material code of wetted parts Ⅱ: Cast Ⅲ: Stainless Steel

60, 150 - single-stage head (m)

2-number of stages of impellers

B, C- the cutting number of the impeller, indicating by A, B, C in turn.

Main Application

AY series pumps were mainly used in petroleum refining, petrochemical, and chemical industry. They were mainly applied in transporting the oil without solid particles, liquefied petroleum gas and other petroleum products, high temperature and high-pressure liquid, flammable liquids.

Structure characteristics

AY series single and two stage oil pumps could be divided into six kinds of structures. They were single-stage single-suction, single-stage double-suction, two stage single suction cantilever, single-stage double suction and two stage single suction, two stage double suction supporting type.

The radial part of the shell was especially suitable for conveying high temperature and high pressure, inflammable, explosive or toxic liquids. The installation method was horizontal enter line support. Pump suction flange and the outlet flange were cast on the pump body and were both vertical upward. The seal cavity (stuffing box) and pump cover were cast into a whole, it could be filling sealing and balanced type, bellows type and the series of mechanical seal. The shaft seal chamber had an alternative water-cooled cavity jacketed outside, water cooling cavity was equipped with a special request or it was used when the temperature of the water as transmission medium was over 66℃ and the temperature of hydrocarbon was over 150℃.

The impeller was integrally cast, through static balance, the axial force of pump was mainly balanced by the impeller balance hole.

The bearing body was provided with a set of radial ball bearing and a set of back-to-back mounting thrust ball bearing, and the bearings adopted Oil slinger thin oil lubrication, the surface of bearing body was cast a heat sink, for the air cooling(T<120℃), also could chose fan cooling (T:120℃~260℃) and water cooling (T:260℃~420℃).

In order to easily disassemble the impeller, shaft, bearing, seal and other components without removing the suction or discharge pipe during the pump maintenance, the AY type oil pump adopted flexible diaphragm type lengthened coupling components.

Steering: pump rotated in a counterclockwise direction from the original motivation.

Pump pipeline system

Cooling water was used to cool the shaft seal control, bearing and pump bracket based on the temperature and use requirements. The flow of water of every single line was suggested to be set as 0.3~0.7 m3/h, the pressure was 0.2~0.3 Mpa.

The material of Flow components list

| Material | I | II | III | |

| Temperature | -20℃ ~ +150℃ | -45℃ ~ +420℃ | -45℃ ~ +420℃ | |

| Part name | Case (Body, Cover) | HT250 | ZG230-450 | 1Cr13Ni |

| Impeller | HT200 | ZG230-450 | 1Cr13Ni | |

| Shaft | 45 | 35CrMo | 3Cr13 | |

| Casing ring | HT250 | HT250 | 1Cr13Mos | |

| Impeller ring | QT500-7 | QT500-7 | 3Cr13 | |

| Casing bolt | Q235-A·F | 35CrMo | 35CrMo | |

| Sealing | 3Cr13 | 1Cr13 | 1Cr13 | |

| Mechanical seal case | 3Cr13 | 3Cr13 | 3Cr13 | |

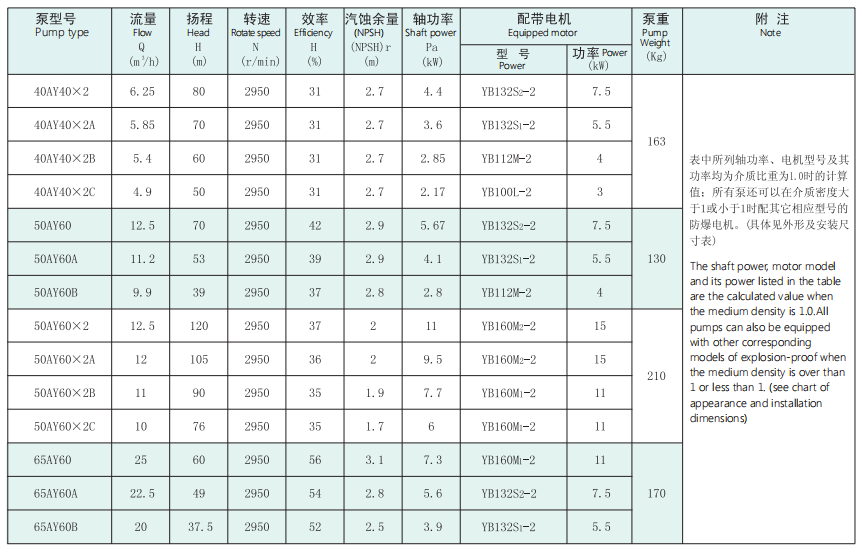

AY type pump performance table

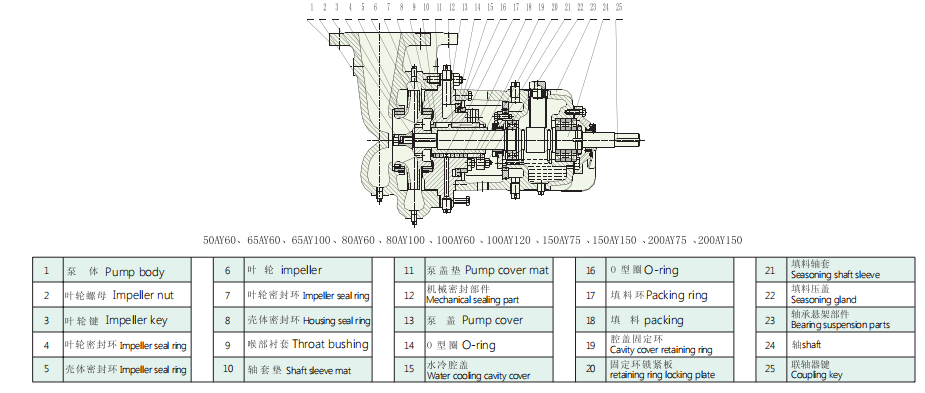

Single-stage single-suction cantilever centrifugal oil pumps structure chart (1)

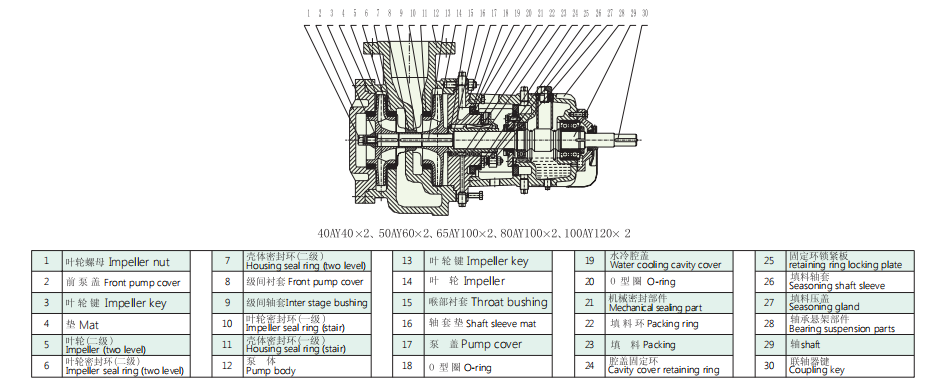

single-suction cantilever centrifugal oil pump structure chart (2)

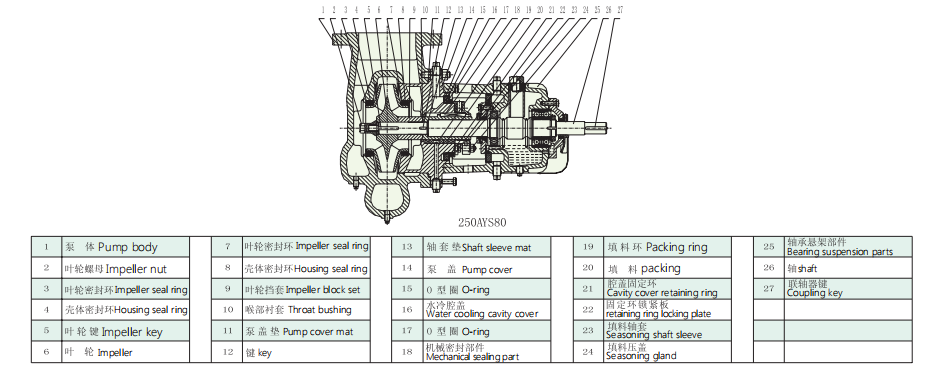

Single-stage two-suction cantilever centrifugal oil pump structure chart (3)

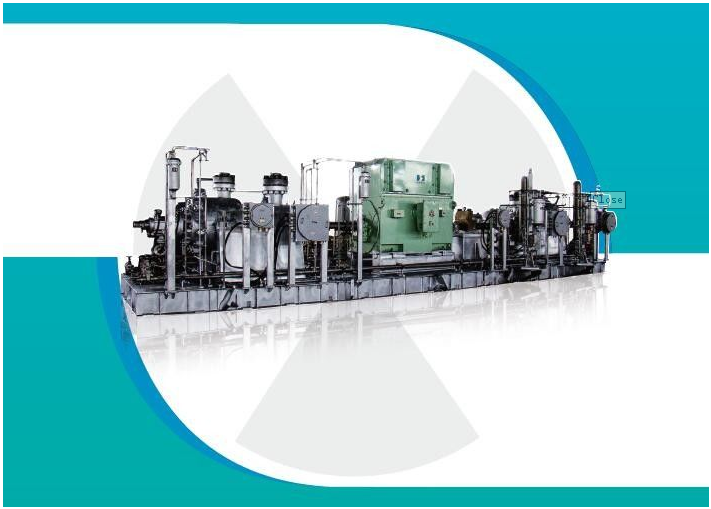

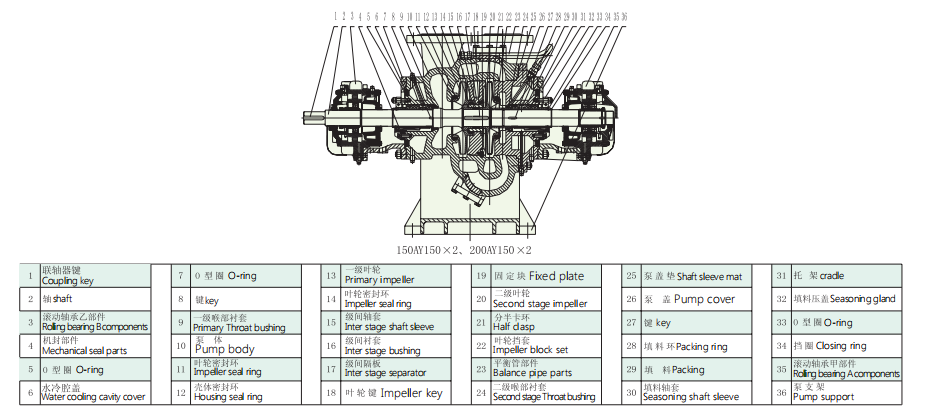

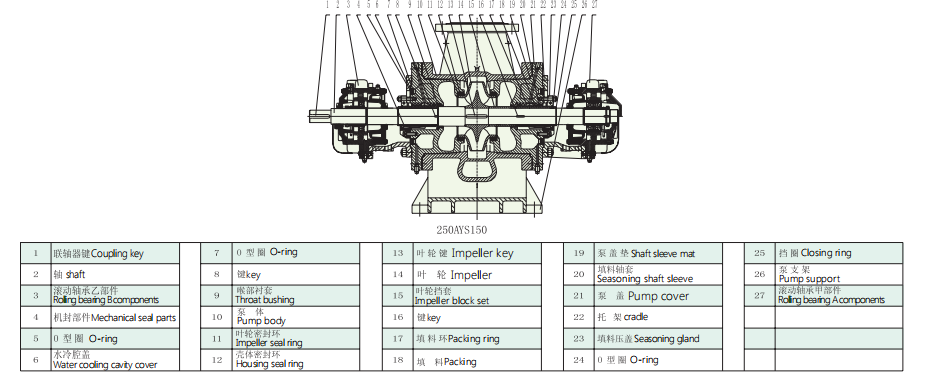

Two-stage single-suction supporting centrifugal oil pump structure chart (4)

Single-stage two-suction supporting centrifugal oil pump structure chart (5)

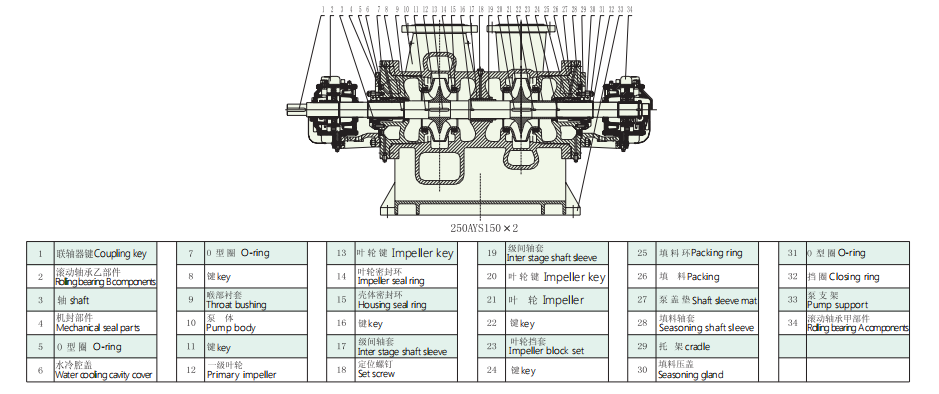

Two-stage two-suction supporting centrifugal oil pump structure chart (6)

-

Centrifugal pumps of AY series for petrochemical industry

-

High-Pressure Hydraulic Turbine Energy Recovery Units

-

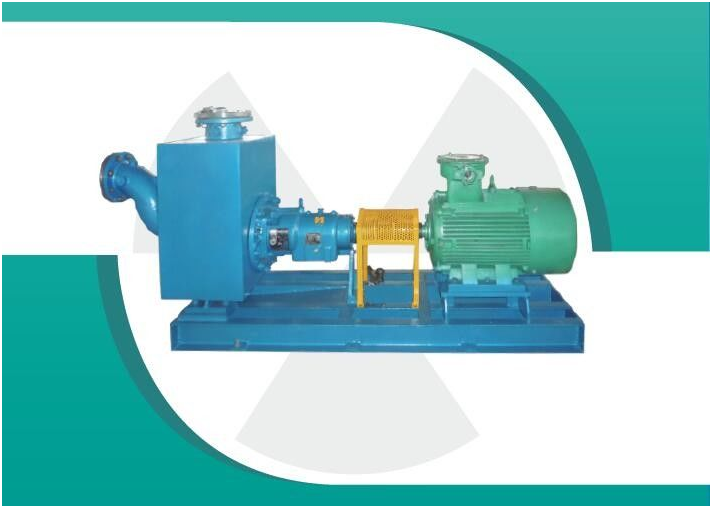

HZX series self-priming centrifugal pumps

-

HX series of small flow chemical centrifugal pump