High-Pressure Hydraulic Turbine Energy Recovery Units

High-Pressure Hydraulic Turbine Energy Recovery Units

Overview

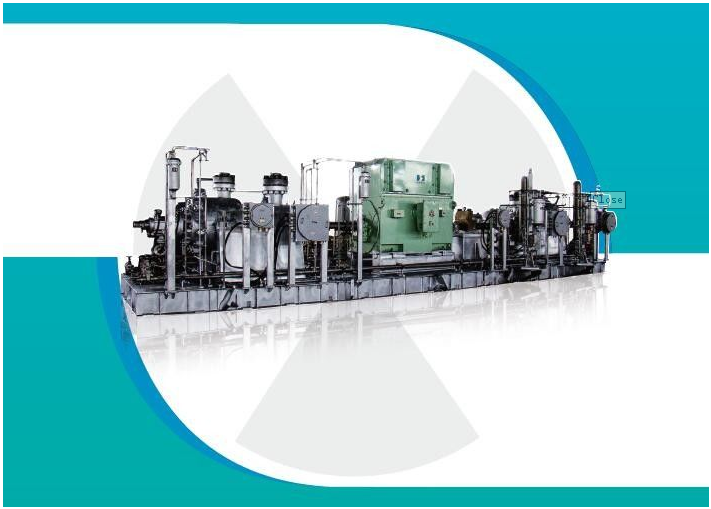

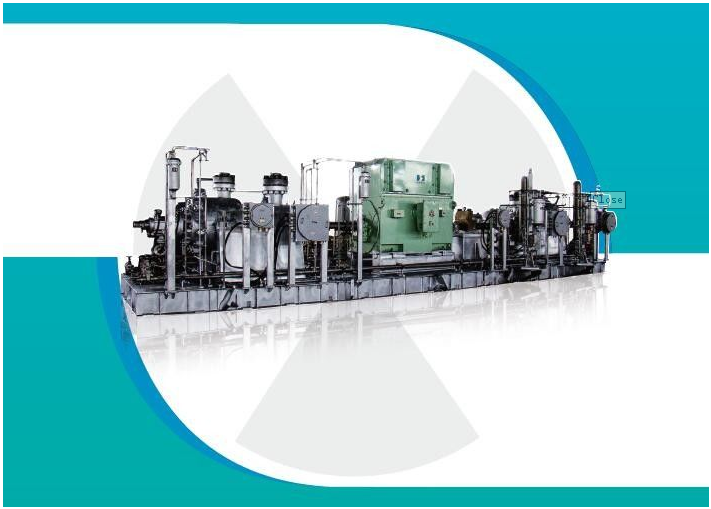

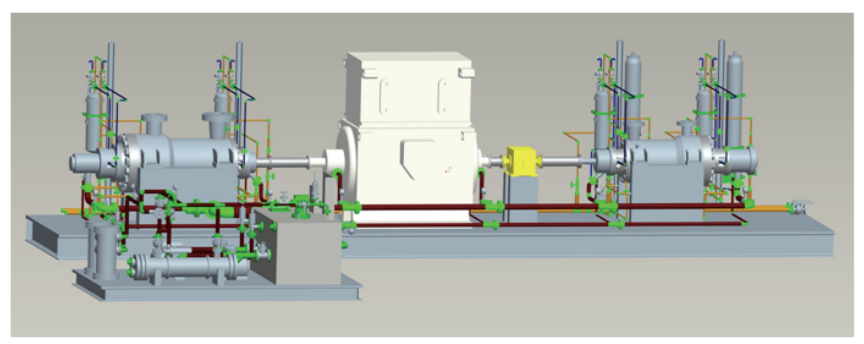

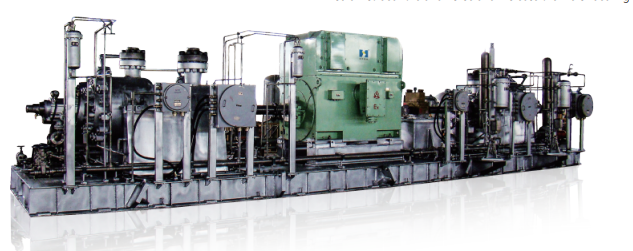

The high-pressure hydraulic turbine is a new high-tech product designed for recovering the remaining energy of High-pressure fluid in petrochemical plants, which meets the requirements of national “Technology Policy Outline” and Appendix C of API610-10TH “The Relevant Provisions of Hydraulic Power Recovery Turbine”. The device gathers all of the achievements in scientific research of our company in recent five years, which owns an excellent application performance, and breaks the foreign monopoly in this kind of products. The recovery power of a single set of hydraulic turbine device reaches more than 500kW, which shows an obvious energy saving. This project has been checked and accepted by SINOPEC, Technological Innovation Projects of Anhui Province and Hefei City. The product’s structure has got the patent of invention “Hydraulic Turbine Device ZL200910144394.7” and utility model patent “Compound Restrictor Ring ZL201020201422.2”. HG/T “Chemical Hydraulic Turbine” formulated by our company has been listed in the Occupation Standard Revision Project of the Ministry of Industry. The product has been successfully applied for hydrocracker units, which has replaced the imported product and gained a remarkable social and economic benefits.

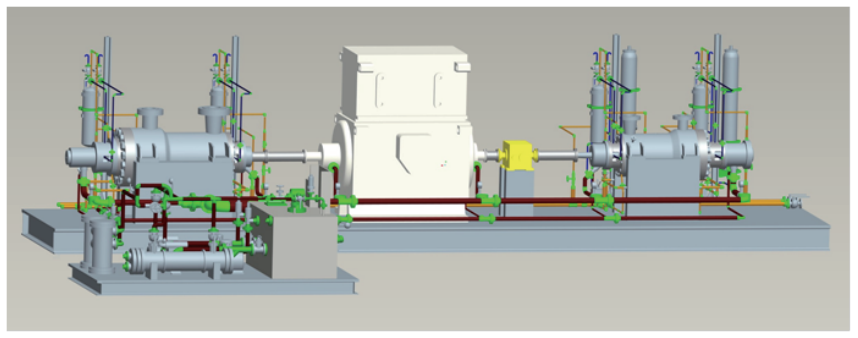

Combination Model of Pump-Hydraulic Turbine Units

Rigid shaft design was adopted in the low-speed turbine, whose rotor system is highly resistant to forced vibration and self-excited vibration, and the application range of the turbine would be wider. Previous petroleum and chemical units were equipped with high-speed turbines. Because more and more problems occurred in operation, then the high-speed turbine was replaced gradually by the low-speed ones recently.

Structure Characteristics

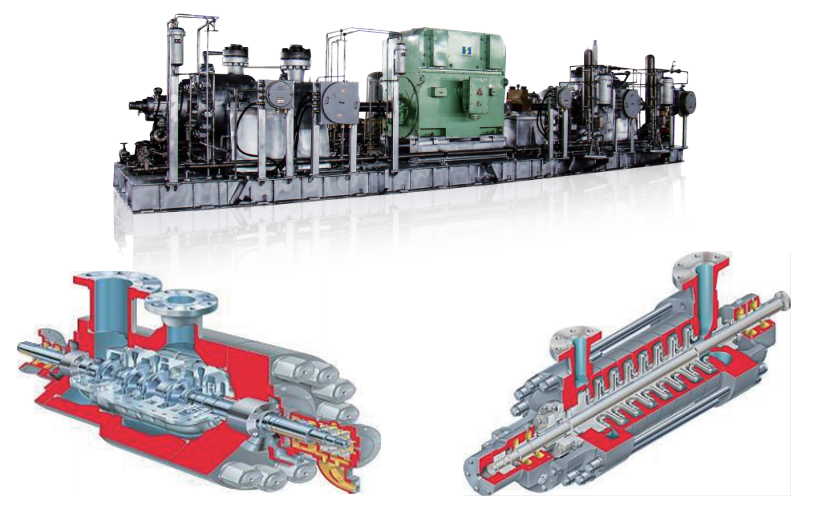

BB5 model horizontal multi-stage double casing with both ends supported structure is adopted in the turbine, which meets the requirements of API. Inlet and outlet locate radially in two sides of the cylinder with two sets of mechanical seal components and bearing parts attached tightly. Externally forced lubrication oil station is used in bearings, which meets the severe working conditions and environments. Condition matching design of impeller and guide vane suits for the specificity of high_pressure and easily vaporized medium and increases the recovery efficiency. Axial force balancing device, which locates in the inlet side, can balance the axial force due to rotors being arranged in the same direction. Rotor system has a rigid shaft design, which increases the strength and rigidity of the shaft and improves the resistant ability of external disturbance and increases the reliability and stability of the hydraulic turbine.

This series of pumps use the drum-plate-drum structure for balance, which can control “Flashing” effectively during operation. Besides, the structure can completely balance the axial force. When working in normal conditions, the bearing would not bear the axial force and increase the life of bearing greatly.

The range of application

Used for hydrofining, hydrocracking and similar occasions in petroleum refining for High-pressure hydraulic energy recovery. The payback period of investment will be 9~18 months.

-

Centrifugal pumps of AY series for petrochemical industry

-

High-Pressure Hydraulic Turbine Energy Recovery Units

-

HZX series self-priming centrifugal pumps

-

HX series of small flow chemical centrifugal pump