HX series of small flow chemical centrifugal pump

HX series of small flow chemical centrifugal pump

Overview

HX series pumps are designed in accordance with ISO/DIS9905 , and the import and export flange dimensions conformed HG20592-97. The structure and dimensions of the single-stage pump are defined by the standard ofin ISO2858.

HX series pumps included single-stage and multi-stage pump. The structure has the following characteristics:

(1) Axial suction and top discharge,

(2) horizontal cantilever,

(3) low specific speed on hydraulics flow components.

(4) Behind of single-stage pump was open structures, we could remove the pump rotor without disassembling the pipeline and motor by using longer coupling. The bearing house of pumps are divided into common type and high-temperature type. Compared with the common type, the high-temperature type has a cooling water jacket to use cooling water to reduce the bearing temperature. According to the medium characteristics or user requirements, the single/double mechanical seal, tandem mechanical seal, packing seal could be selected, what’s more, Vice impeller dynamic seal could be chosen in the single-stage pump. Sealing parts have a jacketed cavity which could connect external cooling water or low-pressure steam to cool or keep warm.

HX series of small flow chemical centrifugal pumps are suitable for petrochemical, textile, food, medicine, and other industries, it can be used to transport corrosive or non-corrosive, clean or medium containing a small amount of solid particles. In addition, the pumps are used for the situation of low flow or high head.

HX(D) small flow chemical centrifugal pump had won high-tech products award in Anhui province in 2012, and get two patents of utility model invention.

HX series pumps conform to the standards of DIN24256/ ISO2858. The design pressure is 1.6 MPa, and the max use temperature is 400℃.

Type meaning

HX - a b - c * d

HX: Small flow chemical centrifugal pump Code

a: Using temperature (G-high temperature, normal temperature not marked)

b: Flow(m3/h)

c: Single-stage head(m)

d: Impeller stages

For example HXG3.2-32×2 show: Flow: 3.2m3/h, Head: 64m of two (each level 32m) high-temperature low flow chemical centrifugal pump.

Materials

Depending on the transmission medium, pump flow components will use different materials. The following is the material for the main components:

| Part Name | Materials | |||||||||

Pump Impeller Casing cover Sleeve | bronze | 304 | 316 | 304L | 316L | TA2 | Alloy 20 | Monel 400 | Hastelloy B/C | |

| 304 | 316 | 304L | 316L | TA2 | Alloy 20 | Monel 400 | Hastelloy B/C | |||

| Shaft | 2Cr13 or 1Cr17Ni2 | 316 | ||||||||

| Bearing Seat | HT250 | |||||||||

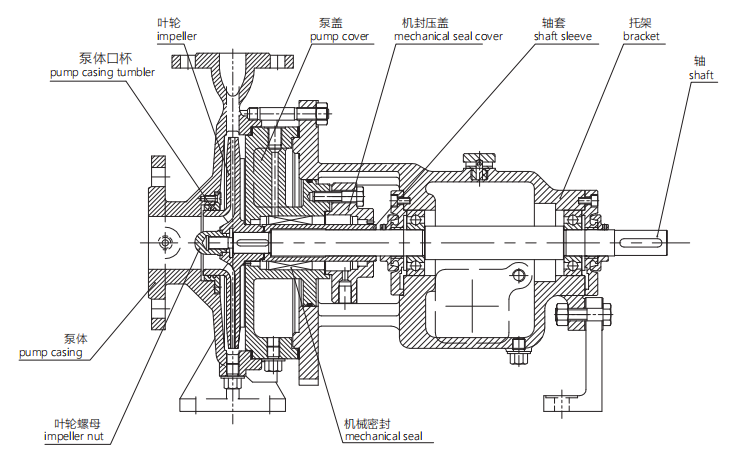

Structure

Series of small flow chemical centrifugal pumps have horizontal, single and multistage cantilever structure, axial suction and radial discharge. For the single-stage pump, when the lengthening flexible coupling is selected, you can replace the seal without disassembling the motor and the pipeline.

From the motor side, the rotation of the pump is clockwise.

HX series of small flow chemical centrifugal pump are divided into common type and high-temperature type. The common types are supported by pump feet, lubricated by bearing grease or oil, the allowable temperature is 105℃. The high-temperature types are supported by pump body center, lubricated by bearings oil, bearing house with a jacket water cooling, and the allowable temperature is 400℃.

Structure diagram

HX single-stage pump performance table

Pump model | Flow Q | Head H | Speed n | Shaft power N(Y=1) | Motor power P | Efficiency η | NPSHr |

| m3/h | m | r/min | kW | kW | % | m | |

| HX1.6-20 | 1.6 |

20 |

2825 | 0.39 | 0.75/1.1 | 22 | 1.0 |

| HX3.2-20 | 3.2 | 0.50 | 1.1/1.5 | 35 | 1.1 | ||

| HX6.3-20 | 6.3 | 0.76 | 1.5/2.2 | 45 | 1.2 | ||

| HX12.5-20 | 12.5 | 1.36 | 2.2/3.0 | 50 | 1.6 | ||

| HX1.6-32 | 1.6 |

32 |

2540 | 0.73 | 1.1/1.5 | 19 | 1.0 |

| HX3.2-32 | 3.2 | 1.00 | 1.5/2.2 | 28 | 1.1 |

Pump model | Flow Q | Head H | Speed n | Shaft power N(Y=1) | Motor power P | Efficiency η | NPSHr |

| m3/h | m | r/min | kW | kW | % | m | |

| HX6.3-32 | 6.3 |

32 |

2840 | 1.37 | 2.2/3.0 | 40 | 1.2 |

| HX12.5-32 | 12.5 | 2.42 | 3.0/4.0 | 45 | 1.6 | ||

| HX1.6-50 | 1.6 | 1.45 | 2.2/3.0 | 15 | 1.0 | ||

| HX3.2-50 | 3.2 | 2.18 | 3.0/4.0 | 20 | 1.1 | ||

| HX6.3-50 | 6.3 |

50 |

2880 | 3.06 | 4.0/5.5 | 28 | 1.2 |

| HX12.5-50 | 12.5 | 4.26 | 5.5/7.5 | 40 | 1.6 |

Pump model | Flow Q | Head H | Speed n | Shaft power N(Y=1) | Motor power P | Efficiency η | NPSHr |

| m3/h | m | r/min | kW | kW | % | m | |

| HX6.3-80 | 6.3 |

80 |

2900 | 6.87 | 0.75/11 | 20 | 1.2 |

| HXG 6.3-80 | 6.3 | 6.87 | 0.75/11 | 20 | 1.2 | ||

| HX12.5-80 | 12.5 | 9.73 | 11/15 | 28 | 1.6 | ||

| HXG12.5-80 | 12.5 | 9.73 | 11/15 | 28 | 1.6 | ||

| HX12.5-125 | 12.5 |

125 |

2930 | 17 | 22/22 | 25 | 1.8 |

| HXG12.5-125 | 12.5 | 17 | 22/22 | 25 | 1.8 |

-

Centrifugal pumps of AY series for petrochemical industry

-

High-Pressure Hydraulic Turbine Energy Recovery Units

-

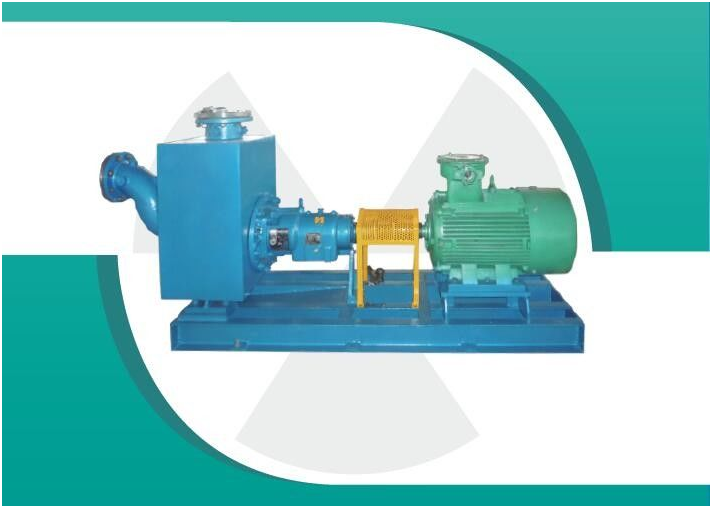

HZX series self-priming centrifugal pumps

-

HX series of small flow chemical centrifugal pump