JQB(JRB, HQG) high shear emulsification and cutting pump in oil chemical industry

JQB(JRB, HQG) high shear emulsification and cutting pump in oil chemical industry

Overview

Mixed operation is widely used in petroleum, chemical, paint, printing and dyeing, water treatment and other industries, it is one of the most widely used chemical operation units. most of the mixing equipments are non-standard equipments, their structure are different from others. High shear homogenizer pump and high shear emulsion pump are recently introduced as a new efficient mixing equipment, and high shear homogenizer pumps are suitable for viscosities between 1500 to 50000CP in the high viscous situation, while high shear emulsifying pump is suitable for low viscosity of less than 1500CP in the low viscosity situation.

High shear homogenizer pump and high shear emulsion pump are designed according to the compact on-line design concept, the material which be treated will carry out to continuous flow, disposable manufactured. Compared with the traditional production process, it eliminates the huge material and dissolved modulation system cans, there is no lengthy reaction time in the lag kettle , it has a small occupied area, good mixing effect, high production efficiency and other characteristics, it has great application value in the modern petroleum generation science industry.

Working principle

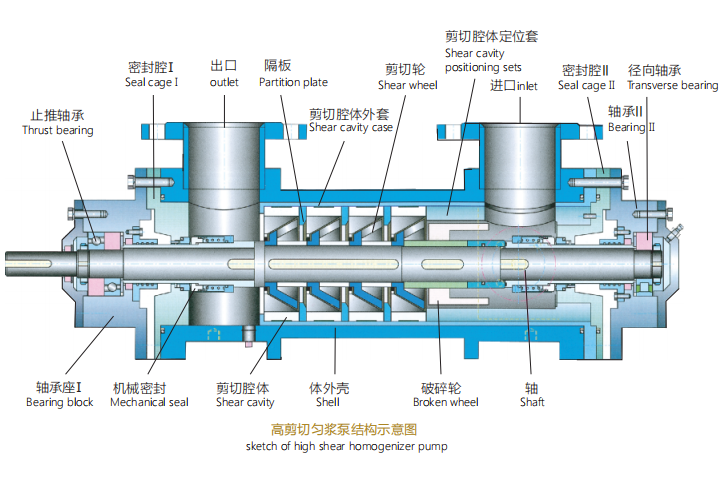

High shear homogenizer pump is suitable for high viscosity multi-component material homogenization process. Its core is a highly effective dispersing shear model, its multi-level, multi-form with a broken rotor parts has cutting, mixing and transport functions. Depending on the different applications, head rotor can adopt jaw broken wheel or spiral inducer to transport or pre-disperse the materials. Cutting the material deeply and high-speed mixing is carried out by the multistage shear wheel which the shear is the rear wheel. Radial clearance between the shear wheel and shear cavity is small, when the material was repeatedly forced to through the diversion holes of stationary shear cavity, the edge of the high speed rotation shear wheel disperse and chop the high viscosity fibrous medium so that one or more of trace phase (solid or liquid) was dispersed uniformly to continuous phase (liquid), then we can make finely and highly uniform mixture rapidly.

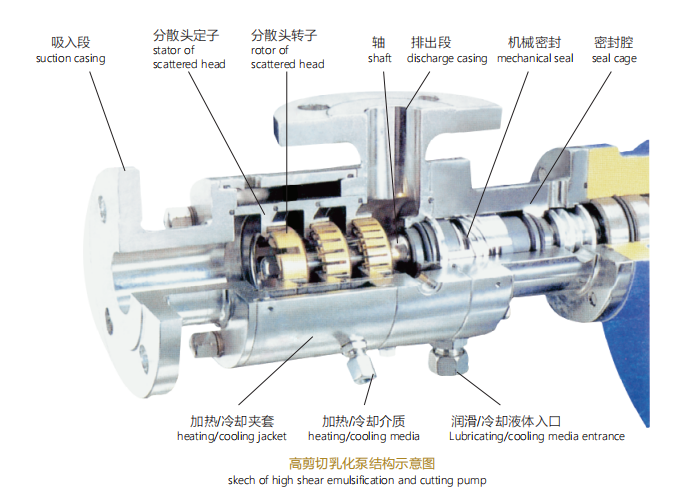

High shear emulsifying pump is suitable for continuous loop handling a low viscosity fine material, it can efficiently, quickly, and evenly distributed multiple phases or one phase to the continuous phase, and the respective phases are incompatible. In the narrow cavity of high shear emulsifying the pump is equipped with the coupling 1-3 group multilayer stator and rotor. When the motor drive the rotor, at high speed, at the center and the outer edge of the rotor will generate a pressure difference, so that the material constantly sucked from import of the pump , and the outer edge of the rotor impact the stator at high speed, and the materials will be injected out from the stator hole, due to the high speed rotation of the rotor generates tangential speed, the material is strongly received hydraulic shearing, centrifugal extrusion, hydraulic friction, impaction ,tearing, turbulence and other combined effects in the narrow gap of rotor, and the immiscible solid phase, liquid phase and gas phase all instantly dispersed emulsion finely under the joint action of the corresponding mature technology and the amount of additive, after a high-frequency cycle, so that the particle size distribution of the material significantly will be narrower, and ultimately we will get a fine, stable and high-quality products.

Structure

JQB series of high shear homogenizer pump, JGSB series of high shear homogenizer dispersed pump (pump speed at 4500rpm or above). The core of the JRB series of high shear emulsifying pump is efficiently dispersed shear model, due to the differences in the nature of the material which will be processed, their structures has different characteristics. Outlet flange of JQB, JRB, JGSB series of high shear emulsifying pump meets SH3406-1996 (PN2.0) standard, the steering of pump is clockwise from the drive view.

Product Features

Generally, JQB, JGSB series of high shear homogenizer pump, JRB series of high shear emulsifying pump has the following features:

1. large process capacity , suitable for industrial online continuous production

2. Particle size distribution of material is narrow, highly uniform

3. No dead runner, the percentage of the material which through dispersing shear is 100%.

4. Save time, efficient, save energy

5. Simple to use, easy maintenance

6. Can completely eliminate the quality difference between batches produced

7. Has a short range, low-lift transport function

8. Low noise, smooth operation

9. Speed and automation can be controlled

Scope of application

Currently, high shear homogenizer pump, the scope of the emulsion pump can roughly cover the following areas:

Fine Chemicals: pigments, plastic additives, filler dispersion, adhesives, emulsion resins, modified plastic, silicone emulsion, hot melt adhesives, sealants, glues, dyes, pastes, slurries finishing agents, surface active agents, leveling agent, carbon black dispersion, anti-blocking agents, release agents, defoamers, fluoride cleaning agents, textile finishing agents brightener, leather auxiliaries, pigment paste, wax emulsion, fungicides, flocculants, coagulants;

Petrochemical industry: oil, heavy oil emulsified diesel emulsion, crude oil emulsion, modified asphalt, emulsified asphalt, wax emulsion;

Biomedical: injections, antibiotics, drugs lotion, medicated cream, health care products, microcapsule emulsion, tissue fragmentation;

Paint and ink: printing inks, paints, architectural coatings, nano-coatings, light-curing coatings, paint additives, carbon black dispersed, automobile paint, printing ink, glaze, bentonite;

Pesticides: pesticides, seed coating, herbicides, medicine cream, fertilizer, pesticide chemicals, green pesticides;

Nanomaterials: dispersion of nano-materials, depolymerization;

Food industry: fruit juice, jam, ice cream, dairy products, food additives, tea drinks, chocolate, soy milk, flavor;

Cosmetic products: liquid detergents, creams, lipsticks, face cream, silicone emulsion, daily flavor, skin care products;

Paper: pulp, adhesives, rosin dispersion, additives, dyes, resins emulsified.

-

Centrifugal pumps of AY series for petrochemical industry

-

High-Pressure Hydraulic Turbine Energy Recovery Units

-

HZX series self-priming centrifugal pumps

-

HX series of small flow chemical centrifugal pump