HZE liquid ring vacuum pumps and vacuum pump unit

HZE liquid ring vacuum pumps and vacuum pump unit

Overview

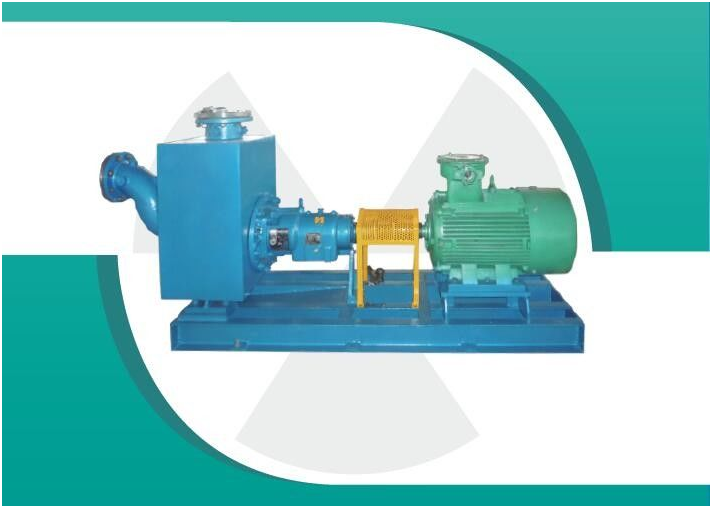

HEZ liquid ring vacuum pump is our company developed energy-efficient products.

The development of the pump is based on years of research and production experience. The pump also combines elements of the international advanced technology. It is typically used for pumping the gas, which is non-solid particles, water insoluble and non-corrosive. In this way, it can form a vacuum in a sealed container. By changing the structure of the materials, it can be used for pumping corrosive liquids. The energy-efficient products are widely used in electricity, paper, coal, petrochemical, chemical, fertilizer, light industry, electronics, pharmaceutical, food, metallurgy, building materials and other industries.

Working principle

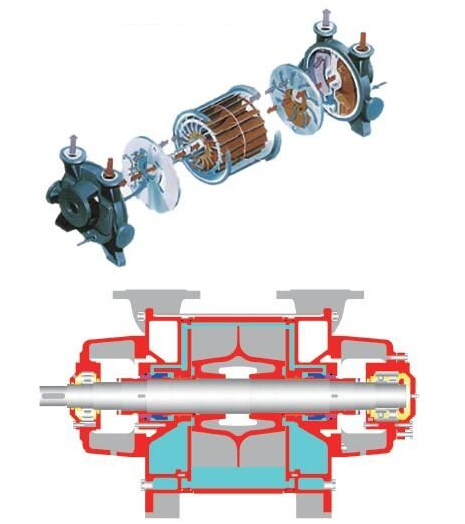

The impeller was eccentrically mounted in the pump body, when the impeller rotates, centrifugal force acts on the fluid, and it will form a liquid ring on pump wall. The gap between the impeller end face and the distributor is liquid sealed. In the first half of the rotation of the impeller (through the suction holes) during the rotation of the volume of the sealed cavity is gradually expanded, the gas sucked by the suction holes; in the latter half of the impeller rotation (through the exhaust vent) during rotation of the sealed volume decreases gas from the exhaust vent, to complete a pumping process. During operation of the pump, to maintain a constant liquid ring, we have to continuously supply the liquid to pump.

Structure characteristics

HEZ liquid ring vacuum pump uses a single-stage with a single-action structure. Since only one rotating member (impeller), and there is no friction between the metal (in fact balance disc is designed to avoid the wear and tear), HEZ liquid ring vacuum pumps can work for many years. A series of optimization designs were used for the key component such as disk, impeller and pump shaft. Structure is simplified and the performance is improved. Balancing the problem was solved by using nodular cast iron welding impeller. Blades have a reasonable profile because of the metal stamping. Interference hot assembly was used for impeller and pump shaft, which made the performance of pump more reliable and the operation of pump more table. After welding impeller, the blade has good toughness because of heat treatment for whole machine. In addition, the blade has good anti-impact and anti-bending ability .It also can adapt to adapt to harsh working conditions.

HEZ liquid ring vacuum pump was equipped with a steam water separator. The steam water separator exhaust port in many locations. The pump cover is provided with an exhaust valve repair window. The gap between the impeller and the disc is adjusted by the positioning bearing ends gland. The pump has the advantages ofeasy to installation, simple to operation, easy to maintenance.

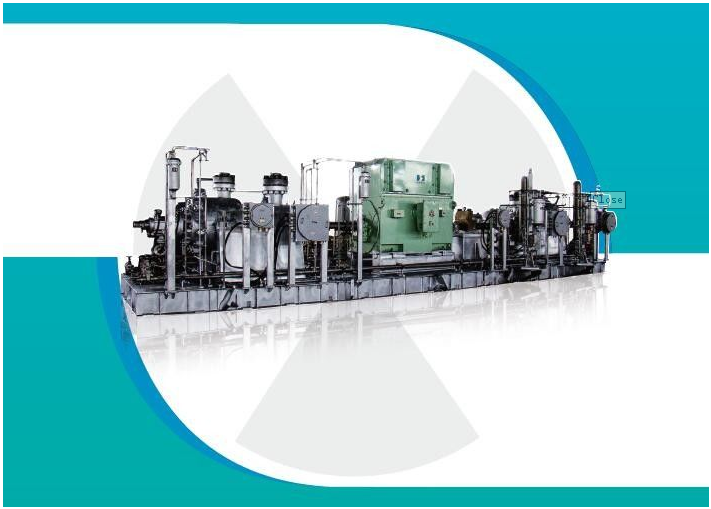

Chemical vacuum pump unit

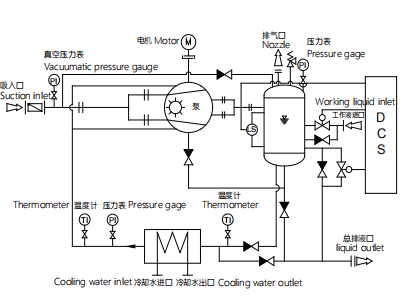

Unit configuration: Equipped with a heat exchanger, gas-liquid separator, safety valve, liquid level control systems, instrumentation and pipeline valve, etc.

The gas to be transmitted:

Air, N2, H2, O2, CO, CO2, H2O, SO2, Hydrocarbons, vinyl chloride monomer, City gas, liquefied petroleum gas, a variety of mixed gas, Acetone, EDC, benzene, ENK, M1BK, cyclohexane, methanol, acetic acid and the like.

Unit configuration features

1. the unit is equipped with a heat exchanger to achieve a closed cycle of the working fluid. Water can be used as working fluid. According to the nature of the transporting medium, ethylene glycol and benzene also can be used as working fluid;

2. the unit is equipped with a gas-liquid separator. The liquid mixture discharged from the vacuum pump can be effectively separated by gas-liquid separator. The separated liquid will be cooled by heat exchanger, and flow back into the vacuum pump to be used as a working fluid. The outlet gas is discharged to the designated place. This pump is suitable for handling flammable, explosive and toxic gases;

3. the unit is equipped with level indicator or sensor to truly reflect the liquid level of gas-liquid separator. The fluid drain valve was controlled by the control signal, which can achieved the automatic liquid level control. There are several ways of level controlling to meet different needs.

4. the electric level control: the gas-liquid separator is equipped with Rehydration solenoid valve, liquid discharge solenoid valve and liquid level sensor. When the liquid level is below the set value, the rehydration solenoid valve will open automatically to complement liquid for unit. When the liquid level restored to the range of set values, the rehydration solenoid will shut down automatically. When the level is higher than the set value, the liquid discharge solenoid valve opens automatically to discharge excess liquid. When the liquid level restored to the range of set values, liquid discharge solenoid valve closes automatically.

5. mechanical automatic level control: The steam separator is equipped with high and low level controller, which can be controlled the high and low liquid level through the working fluid replenishment. The steam separator is also equipped with an overflow device. When the liquid level is higher than the set value, overflow device discharges liquid automatically to control the liquid level.

6. manual level control: When the unit working, the discharged gas will take away a small amount of working fluid vapor, which causes the liquid level drops. According to the display of liquid level gauge, complement the work liquid to unit or discharge the liquid in unit by manually adjusting the rehydration solenoid valve and liquid discharge solenoid valve.

Ordering Information

1. The pump size, material, shaft seal and the motor are determined by the conditions of use. Ordering should be pointed out the displacement, the suction vacuum degree, selected material, the name of the media, the density and temperature.

2. If the pump using special motors, buyers have to point out Explosion levels, power and voltage, frequency, etc.

3. If the pump mechanical seal, the order shall be given the model name.

-

Centrifugal pumps of AY series for petrochemical industry

-

High-Pressure Hydraulic Turbine Energy Recovery Units

-

HZX series self-priming centrifugal pumps

-

HX series of small flow chemical centrifugal pump