HJ(M) chemical metering pumps and dosing devices

HJ(M) chemical metering pumps and dosing devices

Introduction

HJ (M) is a series of improved technology innovation capacity type chemical pump products, divided into the plunger and diaphragm type structure; With innovative design and advanced and reliable hydraulic diaphragm pressure balance control system and multi pressure plunger sealing structure, so that the product has the advantages of high pressure resistance, no leakage etc; And can realize the same base, same specifications of the metering pump multiple combination, also can realize different arbitrary frame, different specifications of the metering pump combination. Suitable for multi-component medium in the process of conveying ratio.

This series of metering pump is mainly used in petroleum, chemical, electric power, atomic energy, medicine and health food, light industry, water treatment, environmental protection, textile and Mining Department. The operational reliability is high. Meet the standard requirements of metering pump GB/T7782-2008.

Suitable for conveying the temperature of -30~150 ℃, solid particle size not larger than 0.1mm, viscosity of 0.3~800mm2/S corrosive or non-corrosive liquid, the measurement accuracy is within 1%. Plunger type metering pump has the advantages of simple structure, low price etc; Diaphragm metering pump has unique advantages of no leakage, high safety, suitable for conveying various inflammable, poisonous, corrosive, strong irritant, radioactive and precious special medium. Diaphragm pump can adopt double diaphragm with diaphragm rupture alarm device. In addition, our company has independent intellectual property rights in the product structure innovation, has made "the high vacuum diaphragm invention patent (license No. ZL200710090961.6)" and "high temperature remote isolation diaphragm metering pump utility patents (license No. ZL201120327804.4)" and "exhaust safety device (license No. ZL201120151765.0)".

According to user's request, all other configuration specifications can be equipped with filter, safety valve, regulator, import and export of explosion-proof motor, variable frequency motor and inverter etc.

Pump structure and operational principle

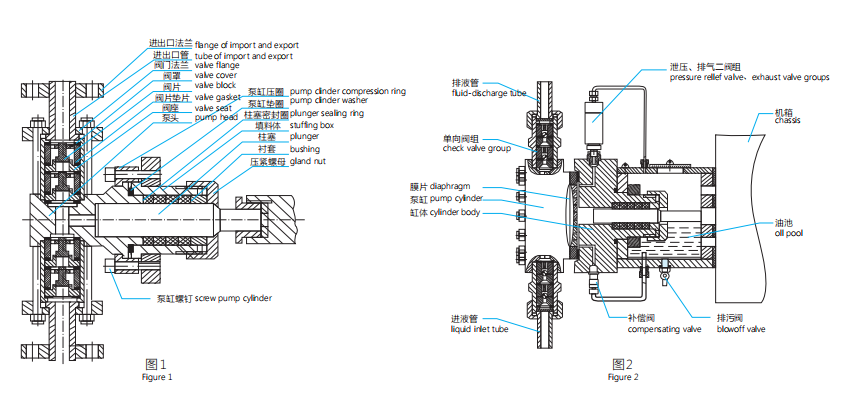

Ⅰ. Pump structure

J series of metering pump is composed of motor, drive end, bracket and a hydraulic end.

1. Drive end structure

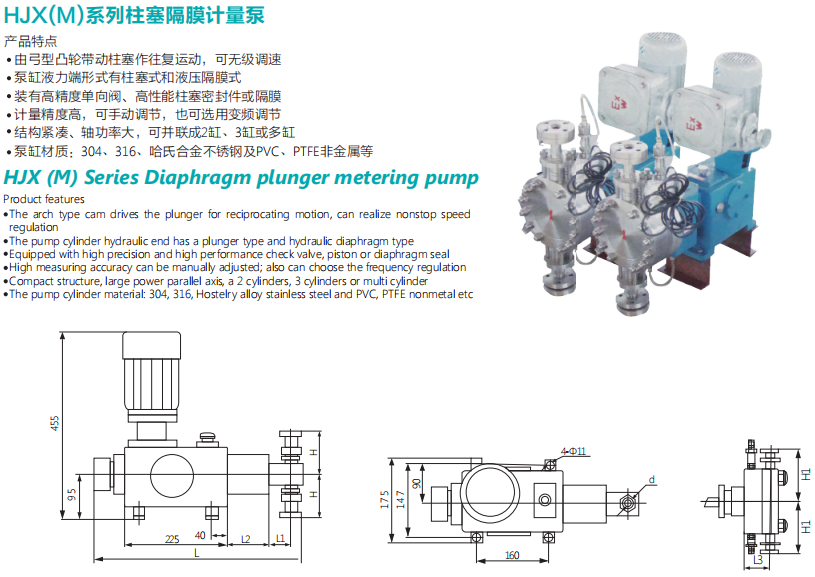

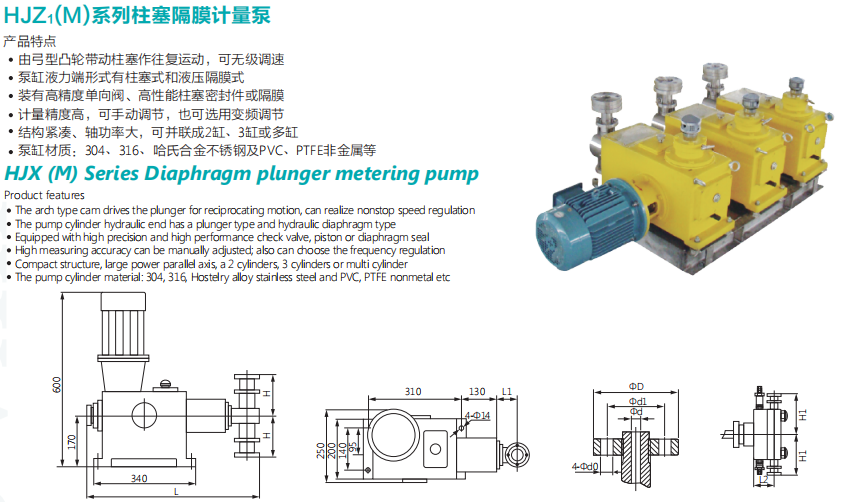

HJZ (M), HJD (M), HJT (M) type transmission box is composed of a worm wheel, a worm, a crank connecting rod mechanism and a travel adjusting mechanism composition, flow control using the advanced N crank variable mechanism. HJX (M), HJZ1 (M) type transmission box is composed of worm gear, worm, bow, cam mechanism, flow control using a bow frame cam mechanism. Its characteristics are: compact structure, adjustable high measuring accuracy, convenient operation and repair.

2. Hydraulic end

(1) Plunger metering pump

It is composed of a pump head, suction check valve group, the discharge valve group (flat or ball valve), plunger, packing etc. (Figure 1)

(2) Diaphragm metering pump

Three valve type submerged fill oil pressure relief vent valve assembly structure located in the top of the cylinders, within a two set of valves are arranged in a valve sleeve. The valve seat and the valve body is composed of a pressure relief valve, plays its protective role of metering pump, when the oil cavity pressure reaches or exceeds the opening pressure, the safety relief valve will automatically open. The safety valve opening pressure can be set. Safety valve core and the deflation valve composed of exhaust valve which can automatically exhaust. Immersion compensation valve is when the plunger moves after hydraulic cylinder of high vacuum, automatically add hydraulic oil cavity. The structure of the plunger is immersed in oil (see Figure 2). Double diaphragm structure is a pressure element associated with pressure sensor device in the middle of two diaphragms. Rupture of any piece of diaphragm will efferent pressure signal to the sensor alarm. The diaphragm can be made of metal diaphragm, composite membrane and multi-phase PTEF diaphragm. The hydraulic end can use a ladder type double seal invention patent structure of piston, automatic oil control valve and distance isolation type hydraulic end with buffer, this would solve the problem of high temperature, high vacuum suction and the use environment of booster inlet.

Ⅱ. Operational principle

The motor through a coupling and worm directly, and drives the worm wheel, the N axis (eccentric) operation, the N axis (eccentric) drives the connecting rod (arch frames) for reciprocating motion, and drives the piston reciprocating motion. When the plunger back check point move, suction one-way valve is opened, the liquid is absorbed in. When the plunger forward check point moves, the suction check valve group is closed, the exhaust check valve group is opened, and the liquid is discharged out of the pump body, so that the pump achieved the purpose of liquid smoke platoon.

The principle of hydraulic diaphragm pump is piston reciprocating motion in the diaphragm in the hydraulic cylinder, the hydraulic oil cavity driven diaphragm occurring reciprocating bending deformation, and then makes medium cavity volume between the cover and the diaphragm changes, through the role of one-way valve so as to achieve the purpose of absorbing and discharging liquid. Because the plunger and the transmission medium are separated from the diaphragm, the validity period of the diaphragm and can ensure the medium without any leakage.

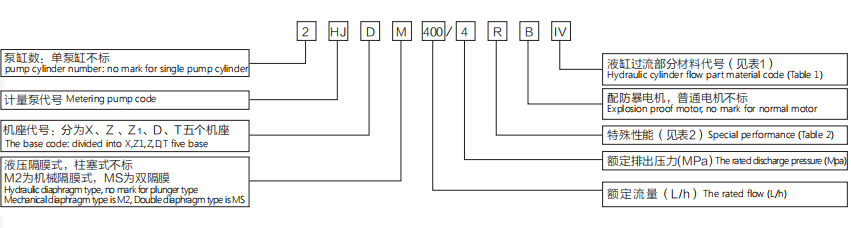

Model demonstration

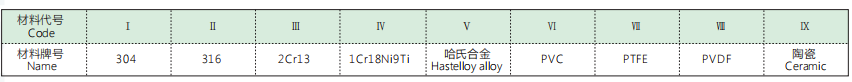

Table1 Hydraulic cylinder flow part material

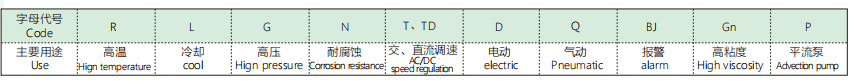

Table2 special performance pump code

Related accessories and parts of pump

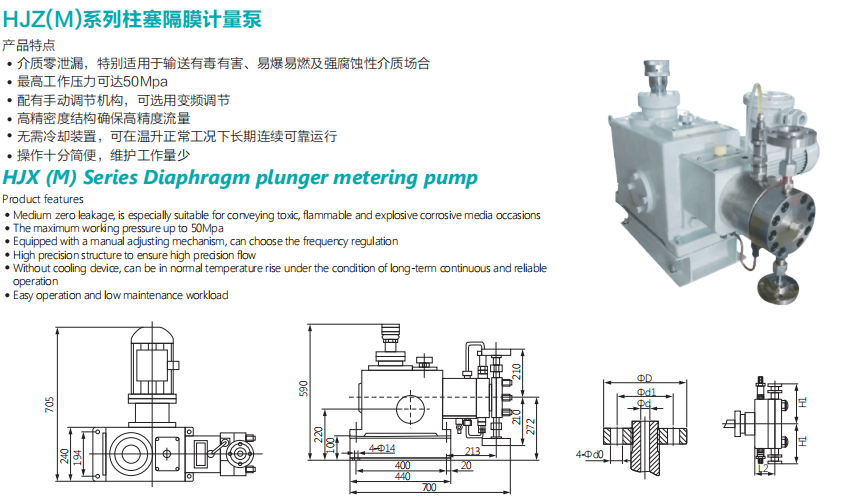

HJX (M) Series Diaphragm plunger metering pump

HJX (M) series plunger diaphragm metering pump performance parameters and external installation dimension

type |

flow (L/h) | motor power(kW) | plunger diameter (mm) | stroke (mm) |

stroke times -1 (min ) |

import and export diameter (d)(mm) | dimensions(mm) | ||||||

| 0.37 | 0.55 | ||||||||||||

| discharge power(MPa) | H | H1 | L1 | L2 | L3 | L | |||||||

| HJX(M)1.5/32 | 1.5 | 32 | 6 |

15 |

72 |

6 |

85 |

138 |

44 |

88 |

62 | 455 | |

| HJX(M)3/32 | 3 | 32 | 8 | ||||||||||

475 | |||||||||||||

| HJX(M)4.5/32(40) | 4.5 | 32 | 40 | 10 | |||||||||

| HJX(M)6.3/32(40) | 6.3 | 32 | 40 | 12 |

8 | ||||||||

| HJX(M)9.5/20(32) | 9.5 | 20 | 32 | 14 |

65 | ||||||||

579 | |||||||||||||

| HJX(M)12/15(22) | 12 | 15 | 22 | 16 | |||||||||

| HJX(M)20/10(14) | 20 | 10 | 14 | 20 | |||||||||

| HJX(M)24/8(12) | 24 | 8.0 | 12 | 22 |

15 |

161 |

57 |

170 | |||||

| HJX(M)30/6(9) | 30 | 6.0 | 9.0 | 25 | |||||||||

| HJX(M)38/5(7) | 38 | 5.0 | 7.0 | 28 | |||||||||

597 | |||||||||||||

| HJX(M)45/4(6) | 45 | 4.0 | 6.0 | 30 | |||||||||

| HJX(M)50/3.5(5.5) | 50 | 3.5 | 5.5 | 32 |

165 | ||||||||

| HJX(M)64/3.0(4.5) | 64 | 3.0 | 4.5 | 36 |

75 | ||||||||

| HJX(M)78/2.5(4) | 78 | 2.5 | 4.0 | 40 | |||||||||

| HJX(M)100/1.8(3) | 100 | 1.8 | 3.0 | 45 | |||||||||

| HJX(M)124/1.5(2.2) | 124 | 1.5 | 2.2 | 50 | |||||||||

| HJX(M)150/1.2(1.6) | 150 | 1.2 | 1.6 | 55 | |||||||||

| HJX(M)180/1.1(1.5) | 180 | 1.1 | 1.5 | 60 |

168 | ||||||||

| HJX(M)210/0.8(1.4) | 210 | 0.8 | 1.4 | 65 | |||||||||

| HJX(M)240/1.1(1.5) | 240 | 0.7 | 1.2 | 70 | |||||||||

| HJX(M)280/0.8(1.4) | 280 | 0.6 | 1.0 | 75 | |||||||||

HJX (M) Series Diaphragm plunger metering pump

HJZ1(M) Series Diaphragm plunger metering pump performance parameters and external installation dimension

ype |

flow (L/h) | motor power(kW) | plunger diameter (mm) | stroke (mm) | stroke times |

import and export diameter (d)(mm) | dimensions(mm) | |||||||||

| 0.55 | 0.75 | 1.1 | ||||||||||||||

| discharge power(MPa) | H | H1 | L | L1 | L2 | d0 | d1 | D | ||||||||

| HJZ1(M)3.5/40 | 3.5 | 40 | 6 |

20 |

106 |

6 |

90 |

142 |

616 |

57 |

64 |

13 |

60 |

88 | ||

| HJZ1(M)6/40 | 6 | 40 | 8 | |||||||||||||

| HJZ1(M)10/35(40/50) | 10 | 35 | 40 | 50 | 10 | |||||||||||

| HJZ1(M)14/22(30/40) | 14 | 22 | 30 | 40 | 12 | 8 | ||||||||||

| HJZ1(M)25/12(17/28) | 25 | 12 | 17 | 28 | 16 |

15 |

165 | |||||||||

| HJZ1(M)40/8(10/17) | 40 | 8.0 | 10 | 17 | 20 | |||||||||||

| HJZ1(M)48/6(8/14) | 48 | 6.0 | 8.0 | 14 | 22 | |||||||||||

| HJZ1(M)60/4.5(6.5/11) | 60 | 4.5 | 6.5 | 11 | 25 | |||||||||||

| HJZ1(M)78/3.5(5/8.5) | 78 | 3.5 | 5.0 | 8.5 | 28 | |||||||||||

| HJZ1(M)90/3(4.5/7.0) | 90 | 3.0 | 4.5 | 7.0 | 30 |

201 | ||||||||||

| HJZ1(M)100/2.5(3.0/5.0) | 100 | 2.5 | 3.5 | 6.5 | 32 | |||||||||||

| HJZ1(M)128/2.2(3.0/5.0) | 128 | 2.2 | 3.0 | 5.0 | 36 |

634 |

75 | |||||||||

| HJZ1(M)160/1.6(2.2/4.0) | 160 | 1.6 | 2.2 | 4.0 | 40 | |||||||||||

224 | ||||||||||||||||

| HJZ1(M)200/1.2(1.8/3.0) | 200 | 1.2 | 1.8 | 3.0 | 45 | |||||||||||

| HJZ1(M)248/1.0(1.5/2.5) | 248 | 1.0 | 1.5 | 2.5 | 50 | |||||||||||

| HJZ1(M)300/0.9(1.2/2.1) | 300 | 0.9 | 1.2 | 2.1 | 55 |

80 | ||||||||||

| HJZ1(M)358/0.7(1.0/1.6) | 358 | 0.7 | 1.0 | 1.6 | 60 |

168 | ||||||||||

| HJZ1(M)420/0.6(0.9/1.5) | 420 | 0.6 | 0.9 | 1.5 | 65 | |||||||||||

| HJZ1(M)490/0.5(0.8/1.2) | 490 | 0.5 | 0.8 | 1.2 | 70 |

25 |

191 |

261 |

655 |

80 |

85 |

85 |

115 | |||

| HJZ1(M)560/0.4(0.7/1.0) | 560 | 0.4 | 0.7 | 1.0 | 75 | |||||||||||

| HJZ1(M)638/0.3(0.6/0.9) | 638 | 0.3 | 0.6 | 0.9 | 80 | |||||||||||

| HJZ1(M)720/0.3(0.5/0.9) | 720 | 0.3 | 0.5 | 0.9 | 85 | 267 | 88 | |||||||||

| HJZ1(M)800/0.3(0.5/0.8) | 800 | 0.3 | 0.5 | 0.8 | 90 | 284 | 89 | |||||||||

HJX (M) Series Diaphragm plunger metering pump

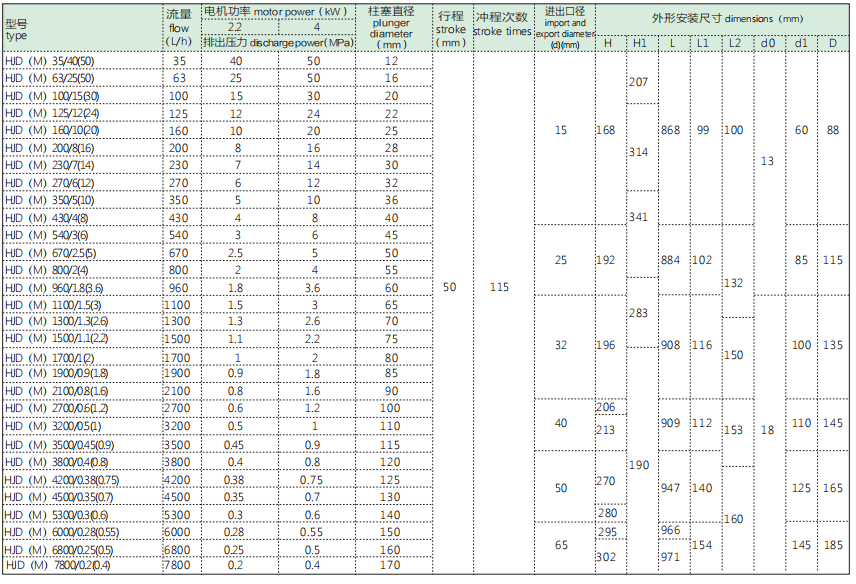

HJZ (M) Series Diaphragm plunger metering pump

type |

flow (L/h) | motor power(kW) | plunger diameter (mm) | stroke (mm) | stroke times | import and export diameter (d)(mm) | dimensions(mm) | ||||||||

| 0.75 | 1.5 | ||||||||||||||

| discharge power(MPa) | H | H1 | L | L1 | L2 | d0 | d1 | D | |||||||

| HJZ(M)9/40(50) | 9 | 40 | 50 | 8 |

32 |

102 |

10 |

96 |

203 |

668 |

75 |

86 |

13 |

60 |

88 |

| HJZ(M)14/35(50) | 14 | 35 | 50 | 10 | |||||||||||

| HJZ(M)21/25(50) | 21 | 25 | 40 | 12 |

161 | ||||||||||

| HJZ(M)38/12(50) | 38 | 12 | 50 | 16 | |||||||||||

| HJZ(M)60/8(40) | 60 | 8 | 40 | 20 | |||||||||||

| HJZ(M)72/7(35) | 72 | 7 | 35 | 22 |

15 | ||||||||||

| HJZ(M)93/5(30) | 93 | 5 | 30 | 25 | |||||||||||

| HJZ(M)110/4.5(25) | 110 | 4.5 | 25 | 28 | |||||||||||

| HJZ(M)130/4(20) | 130 | 4 | 20 | 30 |

224 |

90 | |||||||||

| HJZ(M)150/3.5(16) | 150 | 3.5 | 16 | 32 |

165 | ||||||||||

| HJZ(M)190/3(12) | 190 | 3 | 12 | 36 | |||||||||||

| HJZ(M)240/2(10) | 240 | 2 | 10 | 40 | |||||||||||

| HJZ(M)300/1.8(8) | 300 | 1.8 | 8 | 45 | |||||||||||

| HJZ(M)380/1.5(5) | 380 | 1.5 | 5 | 50 |

240 | ||||||||||

| HJZ(M)450/1.2(3) | 450 | 1.2 | 3 | 55 |

25 |

188 |

688 |

80 |

85 |

115 | |||||

| HJZ(M)540/1(2.6) | 540 | 1 | 2.6 | 60 |

277 |

96 | |||||||||

| HJZ(M)640/0.8(2) | 640 | 0.8 | 2 | 65 | |||||||||||

| HJZ(M)730/0.7(1.9) | 730 | 0.7 | 1.9 | 70 | |||||||||||

281 |

106 | ||||||||||||||

| HJZ(M)840/0.6(1/6) | 840 | 0.6 | 1.6 | 75 | |||||||||||

| HJZ(M)980/0.55(1.4) | 980 | 0.55 | 1.4 | 80 | |||||||||||

| HJZ(M)1080/0.5(1.3) | 1080 | 0.5 | 1.3 | 85 |

32

40 |

197 |

720

734 |

105

112 |

18 |

100 |

135 | ||||

| HJZ(M)1220/0.4(1.1) | 1220 | 0.4 | 1.1 | 90 |

305 |

116 | |||||||||

| HJZ(M)1520/0.35(0.9) | 1520 | 0.35 | 0.9 | 100 |

208 | ||||||||||

| HJZ(M)1820/0.3(0.8) | 1820 | 0.3 | 0.8 | 110 | |||||||||||

| HJZ(M)2000/0.28(0.7) | 2000 | 0.28 | 0.7 | 115 |

213 |

110 |

145 | ||||||||

| HJZ(M)2200/0.28(0.6) | 2200 | 0.26 | 0.6 | 120 | |||||||||||

| HJZ(M)2400/0.24(0.55) | 2400 | 0.24 | 0.55 | 125 |

218 | ||||||||||

| HJZ(M)2550/0.2(0.5) | 2550 | 0.2 | 0.5 | 130 | |||||||||||

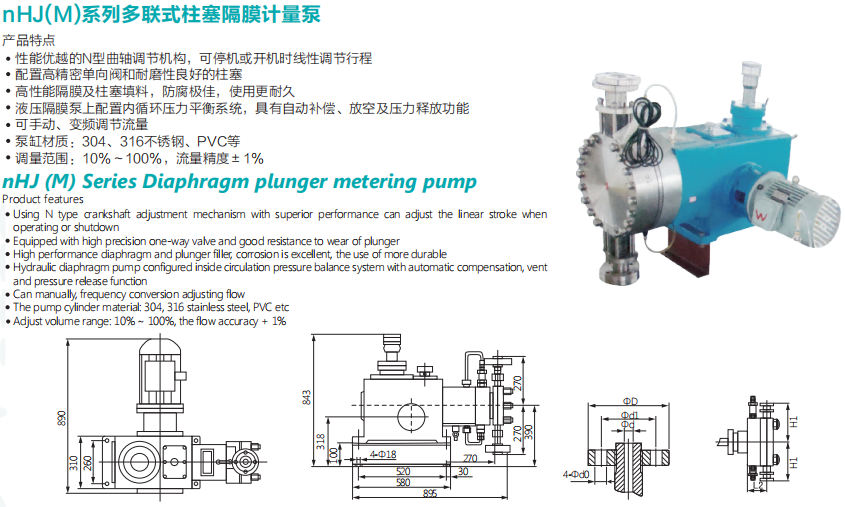

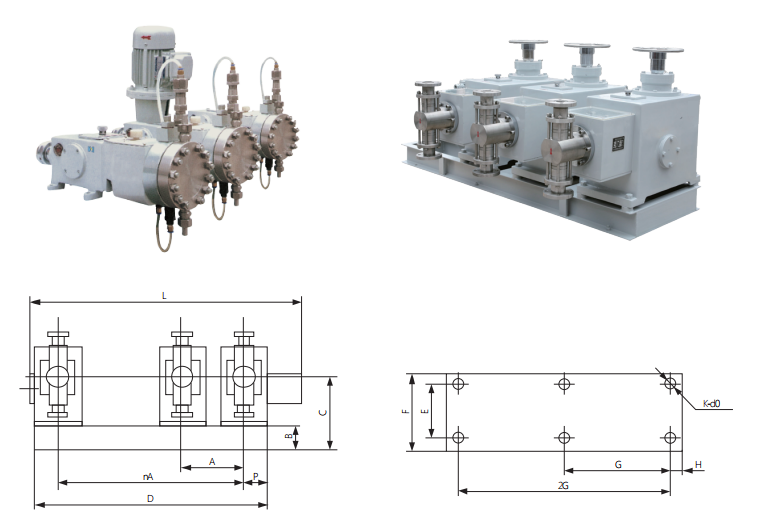

nHJ (M) Series Diaphragm plunger metering pump

nHJ (M) Series Diaphragm plunger metering pump performance parameters and external installation dimension

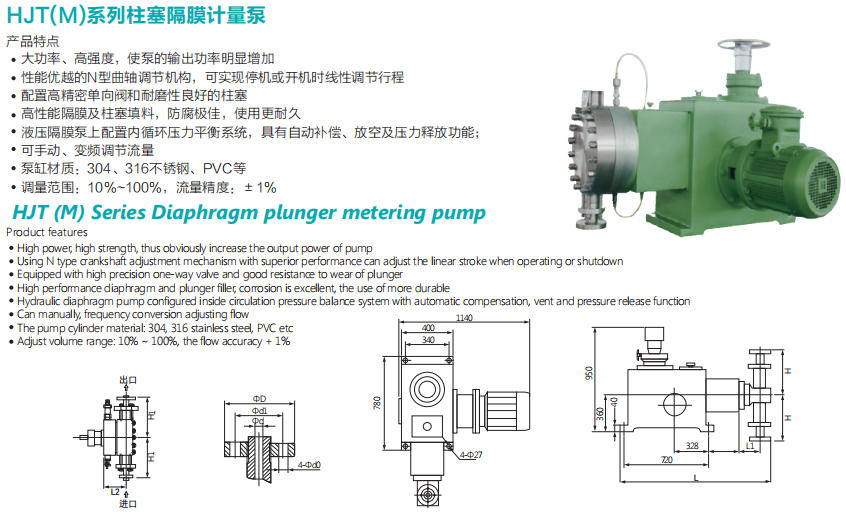

HJT (M) Series Diaphragm plunger metering pump

HJT (M) Series Diaphragm plunger metering pump performance parameters and external installation dimension

type | flow (L/h) | motor power(kW) | plunger diameter (mm) | stroke (mm) | stroke times | import and export diameter (d)(mm) | dimensions(mm) | ||||||||

| 5.5 | 7.5 | ||||||||||||||

| discharge power(MPa) | H | H1 | L | L1 | L2 | d0 | d1 | D | |||||||

| HJT(M)110/45(50) | 110 | 45 | 50 | 16 |

80 |

118 |

15 |

217 |

290 |

1210 |

135 |

61 |

22 |

82.5 |

120 |

| HJT(M)170/40(50) | 170 | 40 | 50 | 20 | |||||||||||

| HJT(M)210/35(50) | 210 | 35 | 50 | 22 | |||||||||||

| HJT(M)270/28(40) | 270 | 28 | 40 | 25 | |||||||||||

| HJT(M)340/22(32) | 340 | 22 | 32 | 28 | |||||||||||

| HJT(M)400/18(28) | 400 | 18 | 28 | 30 | |||||||||||

| HJT(M)450/15(24) | 450 | 15 | 24 | 32 | 320 | ||||||||||

| HJT(M)570/13(20) | 570 | 13 | 20 | 36 |

20 |

222 |

4Φ18 |

89 |

125 | ||||||

| HJT(M)710/10(15) | 710 | 10 | 15 | 40 | 440 | ||||||||||

| HJT(M)900/8(12) | 900 | 8 | 12 | 45 |

90 | ||||||||||

| HJT(M)1100/7(10) | 1100 | 7 | 10 | 50 |

30 | 219 | 630 |

1225 |

141 |

98.5 |

135 | ||||

| HJT(M)1340/5.5(8) | 1340 | 5.5 | 8 | 55 |

230 | ||||||||||

| HJT(M)1600/5(7) | 1600 | 5 | 7 | 60 |

198 | ||||||||||

| HJT(M)1860/4(6) | 1860 | 4 | 6 | 65 | |||||||||||

| HJT(M)2160/3.5(5) | 2160 | 3.5 | 5 | 70 |

50 |

255 |

1251 |

154 |

125 |

165 | |||||

| HJT(M)2500/3(4.5) | 2500 | 3 | 4.5 | 75 | |||||||||||

| HJT(M)2840/2.6(4) | 2840 | 2.6 | 4 | 80 | |||||||||||

| HJT(M)3200/2.4(3.5) | 3200 | 2.4 | 3.5 | 85 | |||||||||||

| HJT(M)3600/2.2(3) | 3600 | 2.2 | 3 | 90 |

180 | ||||||||||

| HJT(M)4420/1.6(2.5) | 4420 | 1.6 | 2.5 | 100 | |||||||||||

| HJT(M)5360/1.4(2) | 5360 | 1.4 | 2 | 110 |

65 |

280 |

1272 |

165 |

8Φ18 |

145 |

185 | ||||

| HJT(M)5860/1.3(1.9) | 5860 | 1.3 | 1.9 | 115 | |||||||||||

| HJT(M)6400/1.2(1.7) | 6400 | 1.2 | 1.7 | 120 | |||||||||||

| HJT(M)6900/1.1(1.6) | 6900 | 1.1 | 1.6 | 125 |

270 |

160 | |||||||||

| HJT(M)7500/1(1.5) | 7500 | 1 | 1.5 | 130 |

292 | ||||||||||

| HJT(M)8700/0.9(1.3) | 8700 | 0.9 | 1.3 | 140 | |||||||||||

| HJT(M)10000/0.8(1.1) | 10000 | 0.8 | 1.1 | 150 | |||||||||||

| HJT(M)11300/0.7(1) | 11300 | 0.7 | 1 | 160 |

80 |

263 |

1387 |

172 |

160 |

200 | |||||

| HJT(M)12800/0.6(0.9) | 12800 | 0.6 | 0.9 | 170 | |||||||||||

| M)14400/0.5(0.8) | 14400 | 0.5 | 0.8 | 180 |

272 | ||||||||||

| HJT(M)16000/0.45(0.7) | 16000 | 0.45 | 0.7 | 190 | |||||||||||

| HJT(M)17700/0.4(0.6) | 17700 | 0.4 | 0.6 | 200 | 277 | ||||||||||

nHJ (M) Series Diaphragm plunger metering pump

nHJ (M) Series Diaphragm plunger metering pump performance parameters and external installation dimension

type | cylinder quantity |

n | A (mm) | B (mm) | C (mm) | E (mm) | F (mm) | 2G (mm) | H (mm) | d0 (mm) |

K | P (mm) | D (mm) | L (mm) |

nHJT(M) | five | 4 |

570 |

130 |

500 |

720 |

785 | 2290 | 200 |

22 |

6 |

210 | 2690 | 3208 |

| four | 3 | 1720 | 200 | 2120 | 2698 | |||||||||

| three | 2 | 1250 | 150 |

4 | 1550 | 2478 | ||||||||

| two | 1 | 780 | 100 | 980 | 1784 | |||||||||

nHJD(M) | five | 4 |

476 |

130 |

420 |

520 |

580 | 1894 | 170 |

18 |

6 |

160 | 2234 | 2858 |

| four | 3 | 1418 | 170 | 1738 | 2382 | |||||||||

| three | 2 | 942 | 170 |

4 | 1282 | 1906 | ||||||||

| two | 1 | 592 | 107 | 860 | 1430 | |||||||||

nHJZ(M) | five | 4 |

378 |

110 |

310 |

380 |

420 | 1466 | 150 |

14 |

6 |

120 | 1766 | 2254 |

| four | 3 | 1088 | 150 | 1388 | 1876 | |||||||||

| three | 2 | 710 | 150 |

4 | 1010 | 1498 | ||||||||

| two | 1 | 418 | 107 | 632 | 1120 | |||||||||

nHJX(M) | five | 4 |

333 |

110 |

282 |

363 |

400 | 1162 | 200 |

14 |

6 |

110 | 1562 | 1909 |

| four | 3 | 829 | 200 | 1229 | 1576 | |||||||||

| three | 2 | 496 | 200 |

4 | 896 | 1243 | ||||||||

| two | 1 | 427 | 168 | 563 | 910 |

HJY series of chemical dosing device

Product features

HJY series of dosing device suitable for petroleum and chemical industry water treatment, boiler feed water, boiler water treatment, treatment of raw water pretreatment, circulating water treatment, environmental protection sewage treatment and seawater desalination processing, can be used to very stable conveying of various chemicals, so as to meet the requirements of process under different working conditions.

The dosing device can be equipped with many kinds of metering pump produced by our company, can also be equipped with imported metering pump as users needs.

Metering pumps, solution tank, electrical control cabinet, buffers, safety valves, valves, piping etc. mounted on a base made with steel, for lifting, installation and operation to bring great convenience which can be designed in various shapes according to the user requirements.

Metering pump on the device can set to the working and standby pumps anyway, where exist two or more solvent tank, through switching the valve, the solution tank can be used interchangeably alone or can be used simultaneously.

Material Flow can be 316 stainless steel,304 stainless steel, Hostelry, duplex steel, carbon steel, carbon steel lining (plastic), PE, PVC and PTFE etc. depending on the requirements of corrosion-resistant.

Depending on the technical requirements, the electrical control cabinet can choose local manual control, semi-automatic control, automatic control and other functions.

-

Centrifugal pumps of AY series for petrochemical industry

-

High-Pressure Hydraulic Turbine Energy Recovery Units

-

HZX series self-priming centrifugal pumps

-

HX series of small flow chemical centrifugal pump