HDS series of heavy oil chemical process pump

HDS series of heavy oil chemical process pump

Overview

HDS series of heavy oil chemical process pump is horizontal, radially split,single-stage, double-stage or three-stage centrifugal with two support ends , pump body is used volute structure and center support structure. It is designed in accordance with API610 standards.

This series pump is designed to meet the need of more harsh and heavy state, it also has the advantages that the structure is safe and reliable, stable to operation,convenient to repair, long to serve etc.

This series of pump hydraulic is based on outstanding hydraulic model of domestic and foreign, it was designed by the 3D modeling and CFD analysis of flow field and other advanced design means, the range of the head and flow of the pump is widely, it also has the characteristic which is high efficiency and the cavitation performance of the pump is good, it is a new generation of high efficiency energy saving products.

Structure characteristics

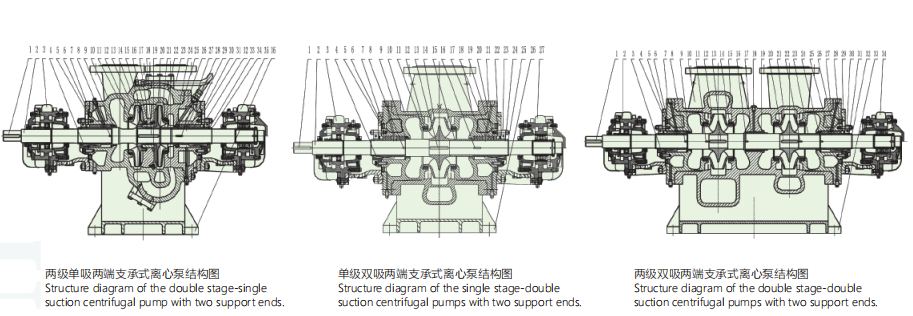

The type of HDS series of heavy oil chemical process pump is BB2 in API610 standard, the structure is divided into single stage-single suction, single stage-double suctions, two stages-single suction, two stage-double suction, two stages-single and double suction and three stages-single and double suction.

Radial split shell is suitable for conveying high temperature and high pressure, inflammable, explosive or toxic liquid. The installation method use the horizontal center line of support; the suction flange and the outlet flange are cast on the pump body, and they are vertical upward; rotor supported at two ends; design for hydraulic parts of the double volute; design for heavy station ; rigid shaft design, conical shaft extension; API 682 seal chamber design.

Impeller is integral casting, and through the static balance, the axial force of pump depends mainly on the impeller balance hole to balance.

The hydraulic part adopts a hydraulic model of high efficiency and energy saving, the average efficiency of the pump is much higher efficiency than the V type oil pump ;

The bearing body is provided with a radial ball bearing and a set of back-to-back mounting thrust ball bearings, the bearings use oil lubrication.

The bearing cooling have air cooling, fan cooling and water cooling, we select the cool method according to different temperature of the pumping medium. The cooling fan is particularly suitable for dry or poor water quality area. The surface of cast has fins, for the air cooling (T<120 C), it also can choose cooling fan (T: 120 to 260 DEG C) and water cooling (T: 260 ~420 ℃).

Pump is easily split into impeller, shaft, bearing, seal and other parts without dismantling the suction or discharging pipe,while maintain it.

Steering: The steering of the pump is counterclockwise direction from the original motivation.

The scope of application

It is widely used in petroleum refining, petrochemical, coal chemical industry, the transportation of crude oil and natural gas processing, offshore drilling equipment and other industrial processes, and it can transport all kinds of neutral or corrosive cleaning medium,neutral or corrosive particle medium.

The typical applications are modern refinery to transport crude oil, tower bottom pump of high temperature and the need for pump continuous operation, barren liquor pump and pregnant solution pump of large synthesis ammonia equipment .

GSB series of high speed pumps structure diagram

-

Centrifugal pumps of AY series for petrochemical industry

-

High-Pressure Hydraulic Turbine Energy Recovery Units

-

HZX series self-priming centrifugal pumps

-

HX series of small flow chemical centrifugal pump