GSB series of high speed pumps

Overview

GSB series of high speed pumps are a novel kind of chemical process pump. It can replace reciprocating pumps and multistage centrifugal pumps in the field of low flow and high head, which can be widely used in petroleum, chemical, electric power, metallurgy, pharmacy, food, environmental protection and other fields. Compared with the same performance of other centrifugal pumps, GSB series of high speed pumps are a type of energy-saving and long-term stability performance product. Components of pumps are less contact with the fluid, so it greatly reduces produce of the corrosion and mechanical failure. Impeller is adopted the flow design of open part of the axial flow, so that the axial force is close to zero. The clearance of the open impeller and the pump body is bigger, which can be used to transport all kinds of high viscosity liquid, and almost don’t affect the pump performance. GSB series of high speed pumps are a strong kind of tolerance pump. It can withstand medium temperature, high pressure, and heavy duty for the user demanding. Styles of Mechanical seals are various and reliable. Mechanical seals use fluid pressure balanced way. They make leaking and the centrifugal force of seal with the opposite direction, sealed compact structure and convenient installation. The common type of mechanical seals is single face balance type. According to working condition, you also can choose double end face type and tandem type. And equip with the necessary flushing, cooling, diluted, discharge and other peripheral

systems, these systems can ensure the used reliability of the mechanical seals. We own modular design and modular structure, so we can quickly supply products. GSB series of high speed pumps are adopted thought of modular design. The structure of whole machine is modular structure, and its parts are high standardization degree and strong commonality. Characteristics of pumps can meet the needs of users of various performance requirements by changing rotational speed, impeller diameter and size of the diffuser, and we can quickly supply products.

Advantages of Installation are economic and convenient. GSB/H series of high speeds pumps structure is suction ejection of horizontal side. Pumps’ installation methods are similar to ordinary chemical process pumps. GSB /V2 type is vertical high speed pump (with big frame), and GSB/V6 type is overloading vertical high-speed pump (with big frame). When pumps equip with more than 90 kW motor power, combination pumps are in vertical frame, where is equipped with adjusting bolt in the pump and motor, and quick with convenient installation. On-site maintenance is easy. Single stage structure can provide maintenance advantages while multi-stage pumps don’t. The repair of Pumps can be done on the scene. The frame of more than 90 KW vertical high speed pumps has lift system on the inside, so you don’t need to remove the motor. You discharge lengthened coupling and the pump body connection bolt, and pull the gear box. You will be able to replace idler, impeller, shaft sleeve and packing, etc. The numbers of parts of pumps are few and have good compatibility. In 2009, GSB high-speed pumps products have been identified as high-tech products in Anhui province. In 2010, the company is responsible for formulating national machinery industry standard JB/T11008-2010 for high-speed partial emission pump, which have been implemented by Ministry of Industry and Information Technology. Our company's GSB high speed pumps products have possessed core patent structure and technology innovation. Among them: ZL200810018471. X, ZL200910116543.9, ZL200920186058.4, ZL201120329759.6, ZL201220305414.1, ZL201120327638.8 and other patents for utility model.

Type meaning

GSB/A-B/C-D-E.F.G.H

A–High speed pumps type belonging to

B - Flow (m3 / h)

C - Head (m)

D - Providing motor power (kW)

E - One percent of the pump rotation rate (n / 100 r/min)

F - The used basic material code for

Pump contact medium parts

I-ZG25;II-ZG1Cr12Ni9;

III-ZGOCR18Ni12Mo2Ti;IV-HarsteLLoy;

G- The installation type of mechanical seals

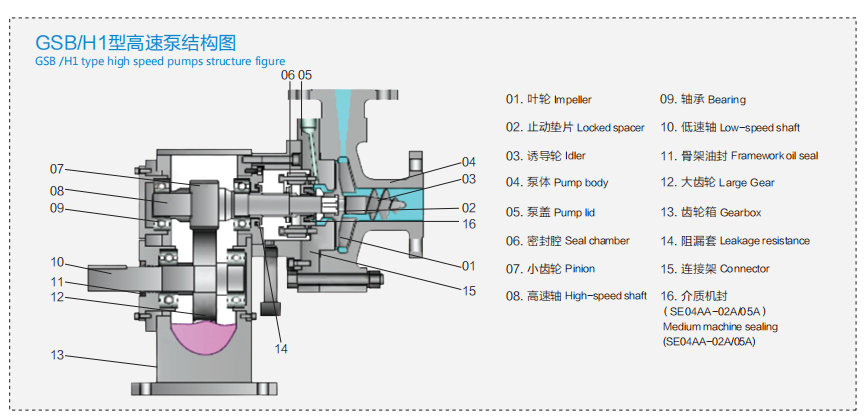

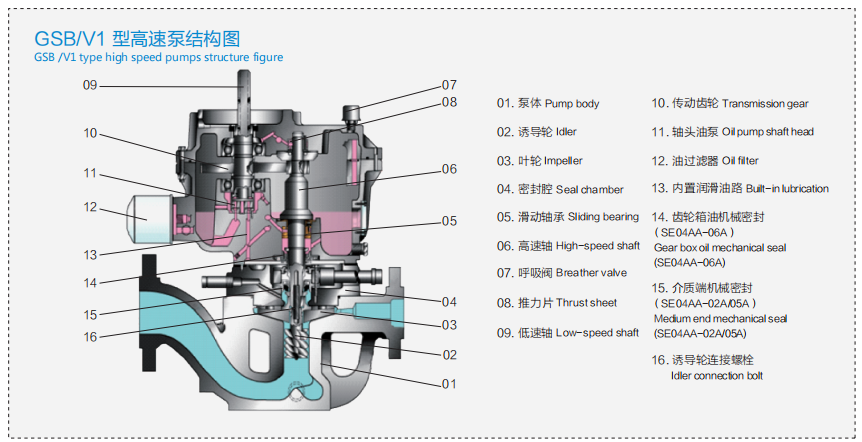

Specifications and structure classifications

| Model | Structural features |

| GSB/H1 | The horizontal end sucked out and ejection, the first level of gear speed up, oil lubrication splash. |

| GSB/V1 | Vertical level inhale vomit, the first level of gear speed up, oil lubrication is forced. |

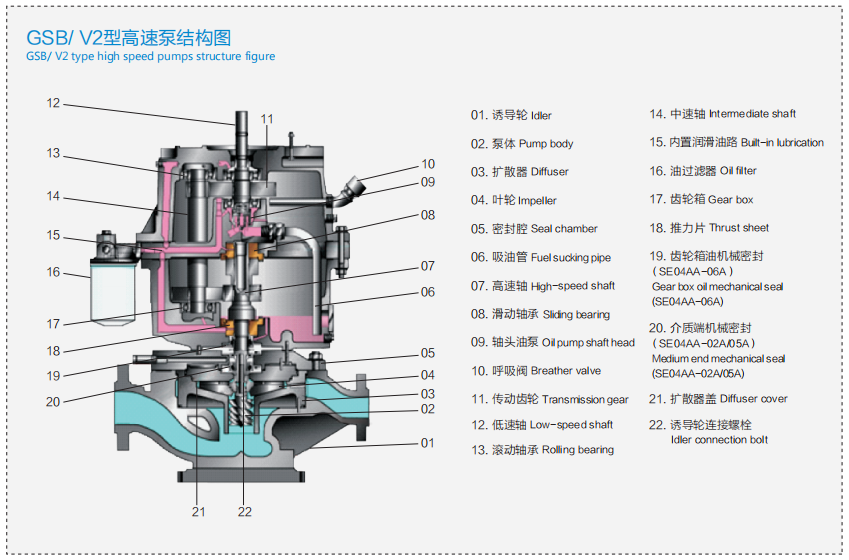

| GSB/V2 | Vertical level inhale vomit, the secondary level of gear speed up, oil lubrication is forced. |

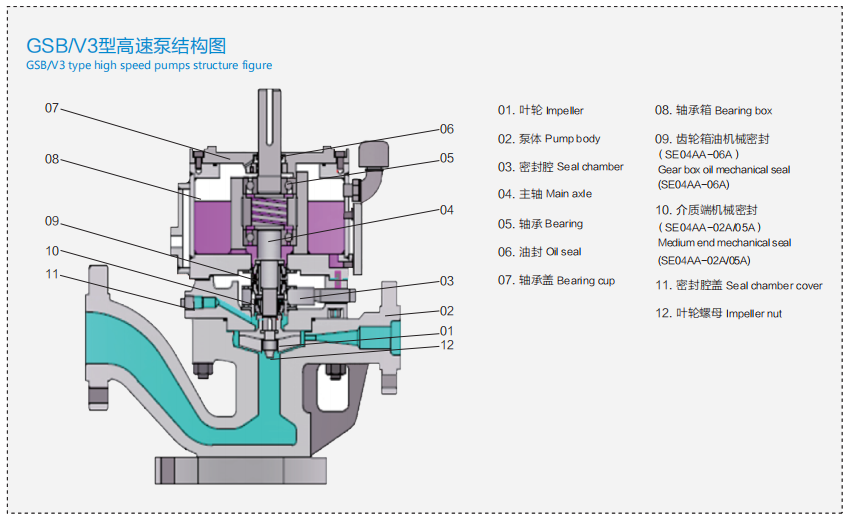

| GSB/V3 | V1 type without gear box, Vertical level inhale vomit, oil bath lubrication |

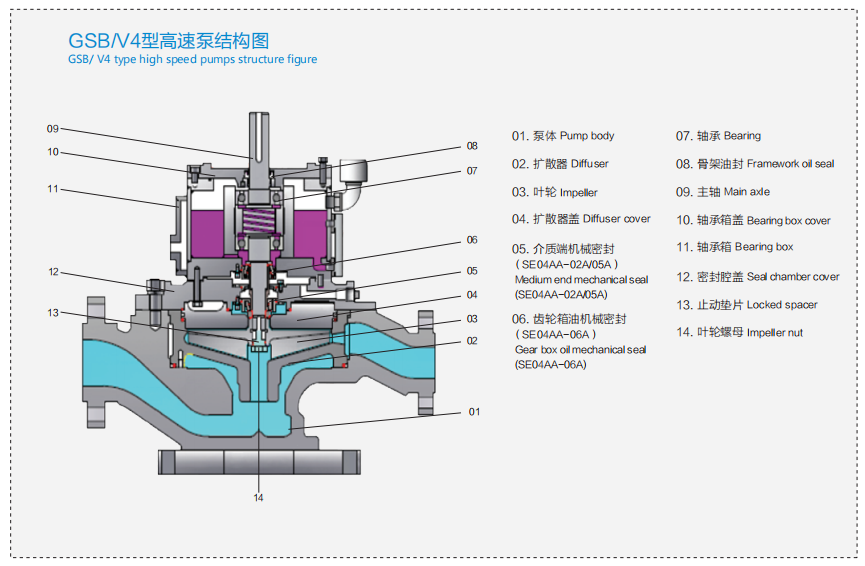

| GSB/V4 | V2 type without gear box, Vertical level inhale vomit, oil bath lubrication |

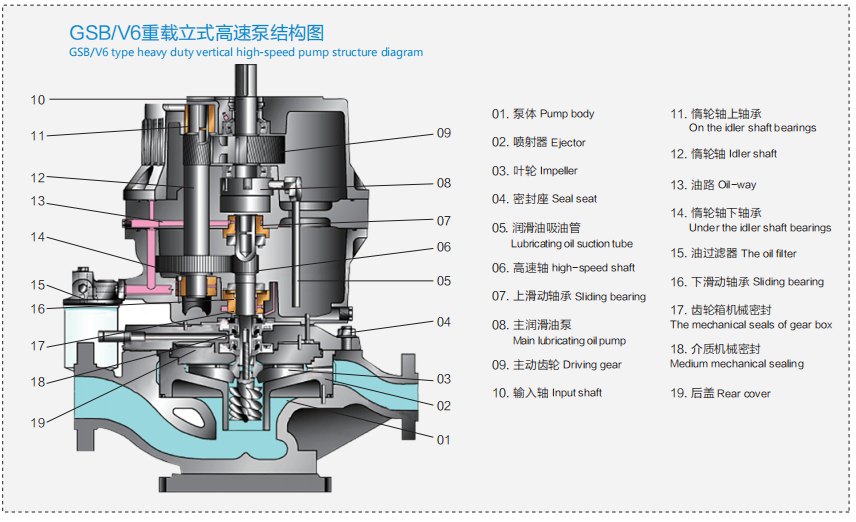

| GSB/V6 | Vertical level inhale vomit, the secondary level of gear speed up, oil lubrication is forced. |

Structure diagram

GSB series of high speed pumps performance table

| Type | GSB/H1 | GSB/V1 | GSB/V3 | GSB/V4 | GSB/V2 | GSB/V6 |

| Maximum flow (m3/h) | 35 | 50 | 75 | 90 | 90 | 90 |

| Maximum head (m) | 300 | 800 | 85 | 154 | 1850 | 2000 |

| The biggest suction pressure (MPa) | 3 | 3 | 2 | 7 | 7 | 3 |

| The maximum work pressure (MPa) | 6 | 8 | 3 | 15 | 15 | 28 |

| The highest rotation rate(r/min) | 8400 | 14200 | 2950 | 2950 | 23700 | 23700 |

| Maximum engine power output (kW) | 30 | 37 | 45 | 55 | 160 | 315 |

| Using the temperature range(℃) | -130~+260 | -130~+260 | -15~+150 | -45~+150 | -130~+260 | -130~+260 |

Application

GSB series of high speed pumps are applicable to transport corrosive, less than 500 centipoise viscosities, flowing medium containing a certain concentration of solid particles. Main purposes:Petrochemical and oil refining: medium transport, loading, reactor feed, recycling and complement, container cleaning. Power: the primary fuel boiler feed and constant pressure differential operation, boiler feed water and preventing overheating and condensation, gas turbine generator fuel pump. Inorganic chemistry: inorganic acid treatment, high pressure washing, boiler feed, synthetic fiber processing. Natural gas processing: coal gasification, natural gas, liquefied natural gas, Synthetic natural gas processing, molecular sieve regeneration and freezing liquefied. Paper: washing operation, high pressure spray operation, sulfite waste liquid mechanical atomizing, condensing boiler feed and preventing overheating. Environmental protection: dehumidification pump of flue washing system, underground waste liquid treatment, eliminating the solid particles, wastewater treatment. Other: such as oil field water injection, rolling detergent hydraulic coal mining, medicine, Circulating water in food processing, boiler feed, etc.

-

Centrifugal pumps of AY series for petrochemical industry

-

High-Pressure Hydraulic Turbine Energy Recovery Units

-

HZX series self-priming centrifugal pumps

-

HX series of small flow chemical centrifugal pump