Annular axial flow pump in oil chemical industry

Annular axial flow pump in oil chemical industry

Overview

The axial flow pump is specifically engineered for the application of PP and PE production as key equipment of the loop reactor. The proven performance and stable parts' lifetime ensuring steady uptime for regular facility maintenances and guaranteed productivity.

Typical performance range

Flow: up to 18000m³/h /80000gpm

Head: up to 45m/150ft

Speed: 1450/1800/2950rpm

MAWP: 100bar/1450psi

Temperature: up to 200℃

Nozzel size: DN150~DN900

Flange: ANSI600lb

Nozzel orientation: end-top

Installation: elastic base, hanging in pipe, with universal coupling

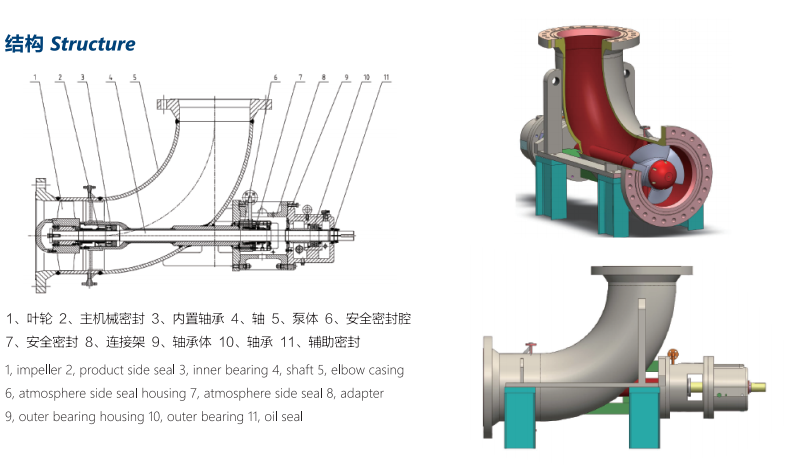

Structure

Structural Characteristics

1. Ensured stability of rotating parts and seals' lifetime;

2. Triple seal arrangement with API seal plans;

3. Primary seal selected to meet MAWP enabling longest seal lifetime;

4. Most heavy duty bearings with cooling ensuring pump stability;

5. Wetted surface finishing 63RMS.

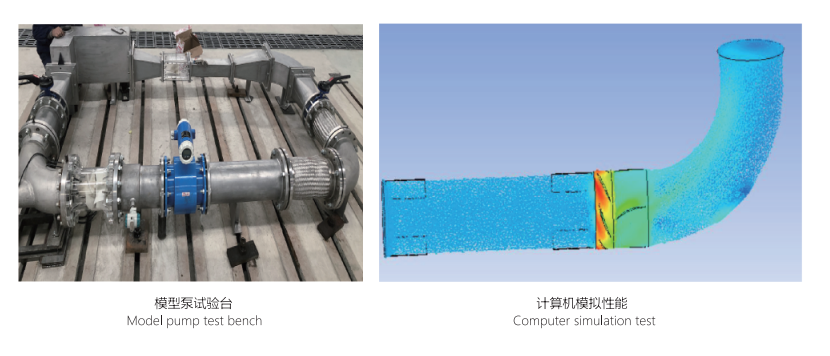

Performance guarantee

Hydraulic developed and simulated with CAD and verified with experiment platform, optimizing against operating condition of each demand, guaranteed pump performance.

Mechanical seal protection system

Triple mechanical seal arrangement with API Piping Plan 32/53C+52, product side seal with API Plan32 system preventing polymerizing by using product compatible fluid as flush fluid. Chamber between product side seal and the inner seal of atmosphere side seal is in accordance with API Plan 53C, pressure of barrier is 10% over than the pressure of API Plan 32 flush fluid. Piston accumulator of the system keeps barrier pressure with pressure of product in loop reactor, which ensures product with no leaking out when seal failure occurs. Outer seal of atmosphere side accommodates API Plan 52, reservoir contains volume of buffer fluid that is capable of remaining at least 8 hours in normal operation. When seal failure occurs, the alarm of the level and pressure switches will be triggered to ensure reliability of sealing system the safety of production.

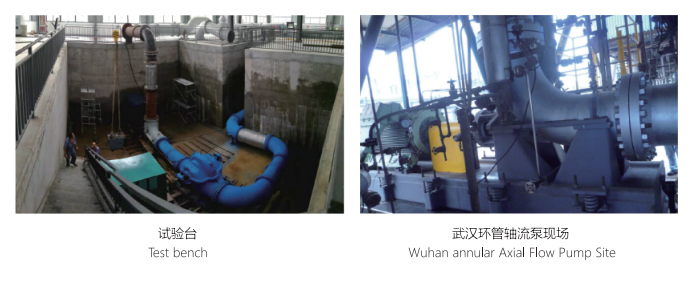

Product show

Order information

1. According to the conditions of use determine the pump size, material, and axial seal type, motor. Please must provide me the name of the media, the properties(density, temperature, vapor pressure, etc.), flow, head, suction pressure and other parameters when ordering;

2. If there are special requirements for the motor, the user should be noted explosion levels, degree of protection, ambient temperature, voltage, and frequency, etc;

3. When you select the axial seal, it must be indicated the type, material, API682 seal piping codes, etc.

-

Centrifugal pumps of AY series for petrochemical industry

-

High-Pressure Hydraulic Turbine Energy Recovery Units

-

HZX series self-priming centrifugal pumps

-

HX series of small flow chemical centrifugal pump