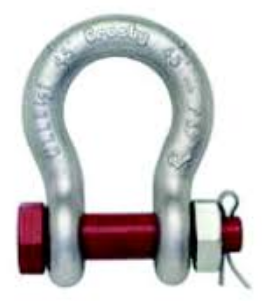

G2130 SHACKLE

G2130 SHACKLE

Product showing:

Description:

Capacities 1/2 to 150 tons

Hot dip galvanized or electric galvanized.

Drop forged, quenched and tempered with alloy pins

Working load limit permanently shown on every shackle

Max proof load is 2.2 times of the working load limited

Min. breaking strength is 6 times or 4 times of the W.L.L. as requirement.

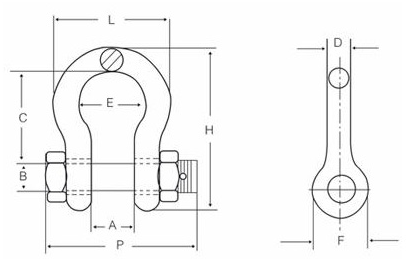

Specification:

The bow shackle is common produce used in the offshore industry, this shackle can be used in temporary and permanent in the mooring system, finish is hot dip galvanized.

Type | Working Load | Dimensions(mm) | Weight | ||||||||

(in.) | (t) | A | B | C | D | E | F | H | L | P | (kg) |

3/16 | 0.33 | 9.7 | 6.4 | 22.4 | 4.8 | 15.2 | 14.2 | 37.3 | 24.9 | 32.8 | 0.03 |

1/4 | 0.5 | 11.9 | 7.9 | 28.7 | 6.4 | 19.8 | 15.5 | 46.7 | 32.5 | 39.6 | 0.05 |

5/16 | 0.75 | 13.5 | 9.7 | 31 | 7.9 | 21.3 | 19.1 | 53.1 | 37.3 | 46.2 | 0.1 |

3/8 | 1 | 16.8 | 11.2 | 36.6 | 9.7 | 26.2 | 23.1 | 63.2 | 45.2 | 55.1 | 0.15 |

7/16 | 1.5 | 19.1 | 12.7 | 42.9 | 11.2 | 29.5 | 26.9 | 73.9 | 51.6 | 63.8 | 0.22 |

1/2 | 2 | 20.6 | 16 | 47.8 | 12.7 | 33.3 | 30.2 | 83.3 | 58.7 | 71.1 | 0.36 |

5/8 | 3.25 | 26.9 | 19.1 | 60.5 | 16 | 42.9 | 38.1 | 106.4 | 74.7 | 89.7 | 0.76 |

3/4 | 4.75 | 31.8 | 22.4 | 71.4 | 19.1 | 50.8 | 46 | 126.2 | 88.9 | 103.4 | 1.23 |

7/8 | 6.5 | 36.6 | 25.4 | 84.1 | 22.4 | 57.9 | 53.1 | 148.1 | 102.4 | 119.6 | 1.79 |

1 | 8.5 | 42.9 | 28.7 | 95.3 | 25.4 | 68.3 | 60.5 | 166.6 | 119.1 | 134.9 | 2.57 |

11/8 | 9.5 | 45 | 31.8 | 108 | 28.7 | 73.9 | 68.3 | 189.7 | 131.1 | 149.9 | 3.75 |

11/4 | 12 | 51.6 | 35.1 | 119.1 | 31.8 | 82.6 | 76.2 | 209.6 | 146.1 | 165.4 | 5.31 |

13/8 | 13.5 | 57.2 | 38.1 | 133.4 | 35.1 | 92.2 | 84.1 | 232.7 | 162.1 | 183.1 | 7.18 |

11/2 | 17 | 60.5 | 41.4 | 146.1 | 38.1 | 98.6 | 92.2 | 254 | 174.8 | 196.3 | 9.43 |

13/4 | 25 | 73.2 | 50.8 | 177.8 | 44.5 | 127 | 106.4 | 313.4 | 225 | 229.8 | 15.38 |

2 | 35 | 82.6 | 57.2 | 196.9 | 50.8 | 146.1 | 122.2 | 347.5 | 253.2 | 264.4 | 23.7 |

21/2 | 55 | 104.9 | 70 | 266.7 | 66.5 | 184.2 | 144.5 | 453.1 | 326.9 | 344.4 | 44.57 |

3 | 85 | 127 | 82.6 | 330.2 | 76.2 | 200.2 | 165.1 | 546.1 | 364.7 | 419.1 | 69.85 |

31/2 | 120 | 133.4 | 95.3 | 371.6 | 91.9 | 228.6 | 203.2 | 625.6 | 419.1 | 482.6 | 120.2 |

4 | 150 | 139.7 | 108 | 368.3 | 104.1 | 254 | 228.6 | 652.5 | 469.9 | 501.7 | 153.32 |

Our advantages:

1.Manufacturing Advantage:

We have more than 20 years experience in anchor chain production.

Our factory is ISO9001 approval, OSHMS18001 approval, ISO14001 approval, API approval and type approval by all IACS members.

Advantage manufacturing facilities:

Advanced program-controlled chain production line; Automatic heat treatment machine; Automatic shot blasting machine.

2.Quality Control:

Manufacturing process quality control from raw material to final product.

Whole set drawing approved by all IACS members; Material Fatigue Test on request; Stress Analysis on request; Stress actual test on quest.

Magnetic power testing, ultrasonic testing, and fluorescent penetrant inspection.

Load test machine up to 4000Ton.

Producion Flow:

Bar Cutting-Bar Heating-Bending-Flash Butt Welding-Trimming-Stud inserting-Pre inspection-Heat treatment-Load test-Final inspection-Painting-Shipment

Service:

We provide drawing design and manufacturing.

Supplied products are anchor, anchor chain, buoy, outfittings, deck equipment etc.

Quick delivery.

Quality products.

Served in marine industry more than twenty years.

Enjoyed excellent reputation from global customers.